Unveiling Precision: The Profound Significance of Histograms in Shao Yi’s Seven Quality Tools Mastery

Introduction:

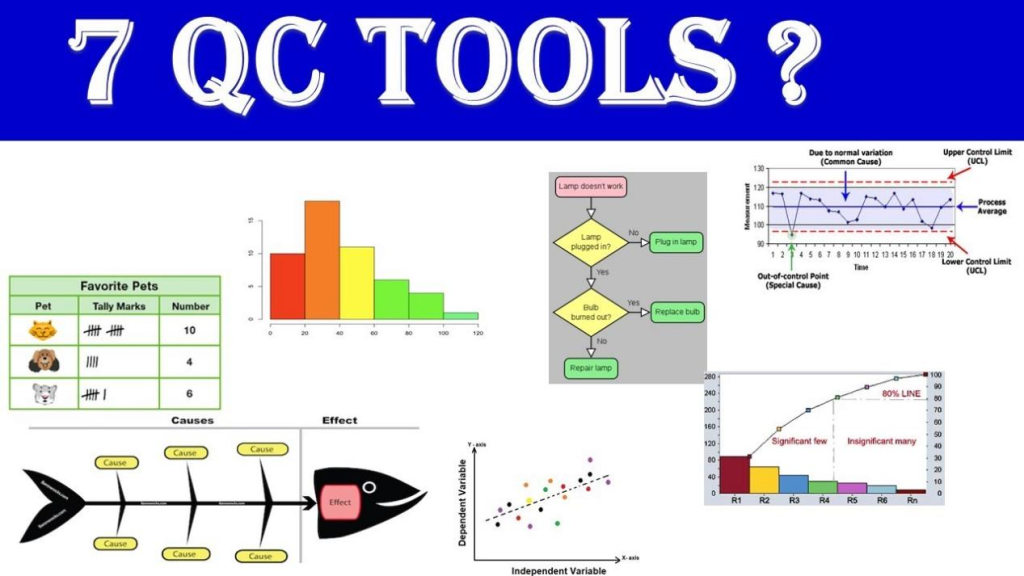

In the intricate realm of precision engineering and automotive manufacturing, Shao Yi stands tall as a bastion of quality excellence. Central to our commitment to delivering impeccable components is the adept utilization of the Seven Quality Tools, with a keen focus on the profound significance of histograms. In this blog, we delve into the intricate meaning and nuanced importance of histograms within Shao Yi’s expertise, unraveling the sophisticated processes that underpin our relentless pursuit of unrivaled quality.

Demystifying the Essence of Histograms:

a. A Visual Chronicle of Data Distribution:

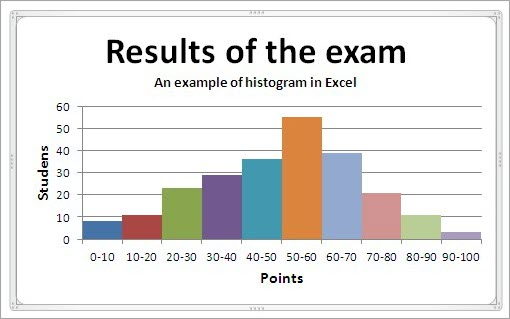

At its core, a histogram is more than a visual representation; it’s a chronicle of data distribution. In the context of Shao Yi’s quality management, histograms serve as a powerful tool for interpreting the distribution of defects, enabling a more profound understanding of the patterns that influence our manufacturing processes.

b. Decoding Frequency and Magnitude:

A histogram, in essence, decodes the frequency and magnitude of defects within a dataset. Shao Yi leverages histograms to discern not just the prevalence of defects but the severity, providing a nuanced perspective that guides strategic decision-making in our pursuit of continuous improvement.

c. Insightful Patterns for Root Cause Analysis:

Beyond a visual depiction, histograms play a pivotal role in root cause analysis. Shao Yi utilizes these graphical representations to identify insightful patterns in defect occurrence, facilitating a targeted approach to addressing the fundamental causes of quality deviations.

Integration within Shao Yi’s Seven Quality Tools:

a. Harmony with Check Sheets:

Within the framework of the Seven Quality Tools, histograms seamlessly harmonize with Check Sheets. Shao Yi employs Check Sheets, a fundamental tool, to tally occurrences of specific defects. Histograms then elevate this data, providing a visual narrative that enriches our understanding of defect distribution across components.

b. Strategic Use in Pareto Analysis:

In the context of Pareto Analysis, histograms serve as a strategic ally. Shao Yi strategically employs histograms to identify the vital few issues that contribute to the majority of defects, empowering our teams to prioritize interventions for maximal impact on overall quality.

c. Augmenting Cause-and-Effect Diagrams:

Histograms play a crucial role in augmenting Cause-and-Effect Diagrams. Shao Yi’s commitment to root cause analysis is fortified by the insightful patterns revealed in histograms, providing a granular understanding of defect frequencies and their correlation with various factors.

Customization for Automotive Components:

a. Tailoring to Component Specifications:

Shao Yi acknowledges that each automotive component is unique in its specifications and quality requirements. Our application of histograms is meticulously tailored, aligning with the specific attributes and quality benchmarks of each component, ensuring a targeted and effective quality analysis.

b. Adherence to Industry Standards:

Shao Yi’s application of histograms transcends internal benchmarks; it rigorously adheres to industry standards and regulations. This meticulous adherence guarantees that our components not only meet internal quality benchmarks but also align with external standards, establishing Shao Yi as a paragon of reliability within the automotive sector.

c. Adaptability Across Diverse Components:

From chassis supports to shock absorber mounts, Shao Yi’s commitment to quality extends across a diverse spectrum of components. The adaptability of our histogram analyses is intrinsic, accommodating the unique characteristics and intricacies of each component type.

Training and Empowering Analysts:

a. Investment in Analytical Proficiency:

Shao Yi recognizes that the effectiveness of histogram analyses is intricately tied to the proficiency of our analysts. Rigorous training programs ensure that our analysts are adept at interpreting histograms accurately and extracting meaningful insights that guide our quality enhancement strategies.

b. Digital Tools for Enhanced Efficiency:

Beyond traditional methodologies, Shao Yi leverages advanced digital tools to augment the efficiency of histogram analyses. Digital platforms empower our analysts to streamline the analysis process, reduce manual efforts, and harness real-time data for decision-making.

c. Fostering a Culture of Analytical Excellence:

More than a procedural task, Shao Yi instills a culture where every team member comprehends the significance of their role in conducting insightful histogram analyses. This collective commitment ensures that the application of histograms becomes an ingrained and expertly executed aspect of our daily operations.

Continuous Improvement and the Feedback Loop:

a. Dynamic Evolution of Analysis Techniques:

Shao Yi views histogram analyses as dynamic techniques that evolve over time. Regular feedback from analysts, coupled with data analysis and insights from the Seven Quality Tools, contributes to the iterative refinement of our analytical methodologies.

b. Operationalizing Corrective Actions:

Beyond identification, histogram analyses form an integral part of the corrective action process. Shao Yi’s commitment to continuous improvement is manifest in a robust system for implementing corrective actions based on findings from histogram analyses, ensuring a perpetual cycle of enhancement.

c. Data-Driven Decision-Making in Real-Time:

The data gleaned through histogram analyses serves as the foundation for real-time, data-driven decision-making. Shao Yi leverages this data to identify trends, anticipate potential issues, and make informed decisions that contribute to the ongoing enhancement of our manufacturing processes.

The Future of Quality Assurance at Shao Yi:

a. Integration of Advanced Analytics:

Shao Yi envisions the seamless integration of advanced analytics, including predictive modeling and machine learning, into the quality assurance process. These advanced analytics have the potential to further enhance the precision and predictive capabilities of histogram analyses, identifying subtle patterns and contributing to a more nuanced understanding of manufacturing processes.

b. Sustainability and Green Practices:

The future trajectory of quality assurance at Shao Yi includes a pronounced focus on sustainability and green practices. Beyond delivering high-quality components, Shao Yi is committed to minimizing environmental impact and promoting sustainable manufacturing processes.

c. Global Benchmarking in Quality Analytics:

As Shao Yi progresses, our aspirations extend to becoming a global benchmark in quality analytics. The application of advanced tools like histograms positions us not only as leaders within the automotive sector but as trailblazers across diverse manufacturing domains.

Conclusion:

In the symphony of precision and quality orchestration, Shao Yi’s commitment to excellence is accentuated by the nuanced application of histograms within the Seven Quality Tools framework. These analyses, far from being mere graphical representations, embody the meticulous approach that defines Shao Yi’s pursuit of unrivaled quality in automotive manufacturing. As we gaze into the future, Shao Yi remains steadfast in its dedication to pioneering innovations, setting new benchmarks, and maintaining the highest standards of quality in every facet of our operations.