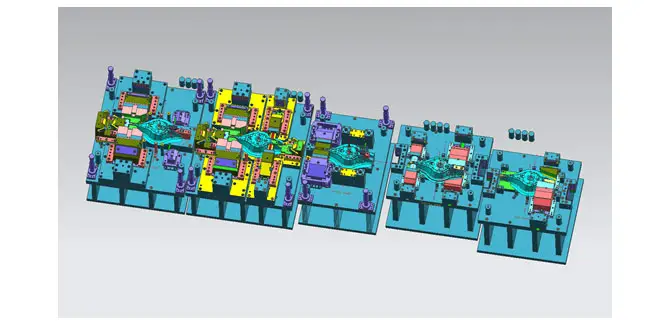

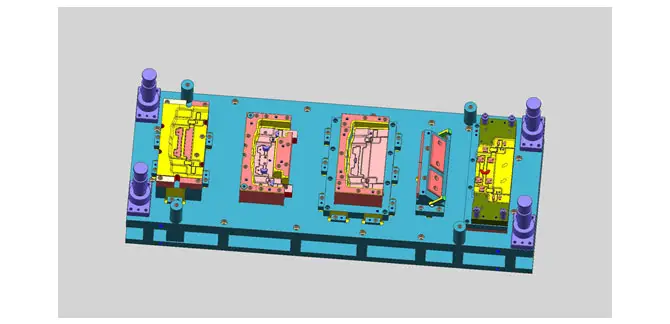

Design and Manufacture Expert of Automotive Stamping Dies

High Precision/Advanced Technology/Custom Solutions

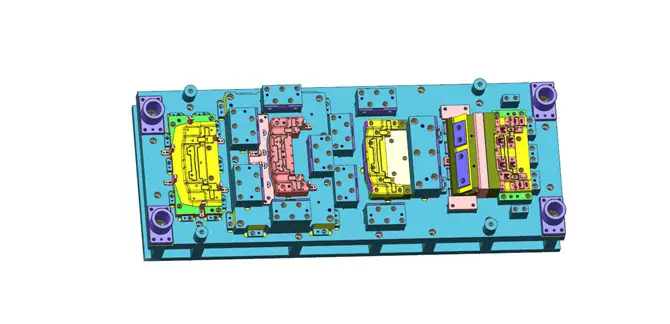

- We specialize in early-stage analysis and bulk production of automotive components, focusing on optimizing automotive metal stamping die solutions to enhance efficiency, precision, and cost-effectiveness.

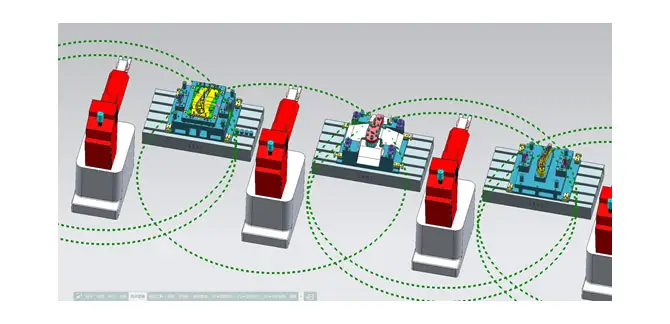

The production management MES system enhances lean manufacturing in stamping die, metal stamping die, and stamped parts production.

• • The customer MES system meets rapid delivery needs for manufacturing die, dies manufacturing, and metal stamping parts.

• • The quality management MES system allows immediate quality feedback and rapid response in metal stamping die and stamped parts production.

• • The MES system for production progress ensures a controllable factory process for dies manufacturing and metal stamping parts.

• • Real-time MES system management enables transparent operations in stamping die, manufacturing die, and stamped parts workflows.

- Various automotive accessories

- Over 12 years of experience in mechanical processing

- Achieve strict precision machining and tolerances

- Consistency between quality and process

- Can achieve customized services

- On time delivery