SHAOYI is a technology-driven enterprise specializing in precision mechanical machining. Established in 2011, we possess over a decade of experience in the research, design, production, and service of automotive parts, electric tool components, and other new energy metal products. With advanced technology, a comprehensive product range, and a strong commitment to superior quality, we have forged partnerships with top 100 domestic automotive parts companies. Our products indirectly contribute to renowned domestic and international automobile brands like VW, Audi, GM, BYD, NIO, Toyota, Honda, and Hongqi.

SHAOYI specializes in precision machining and manufacturing of automotive metal parts, supported by a professional technical research and development team comprising experts in structural design, CAE analysis, mold development, project management, and process planning. Our innovative spirit has led to the acquisition of several patented technologies. We embrace intelligent digital management principles and have invested in automated production and testing lines, while implementing ERP and PLM information management systems.

SHAOYI’s commitment to quality is underscored by our IATF16949 quality system certification. We continuously foster innovation, promote intelligent manufacturing, and implement efficient digital management, all while maintaining a rapid response mechanism. Our service ethos includes swift quoting, rapid prototyping, and round-the-clock customer support. Our aspiration is to stand out as a premier precision metal component manufacturer and service provider for the automotive industry, dedicated to delivering the best possible service to our valued customers.

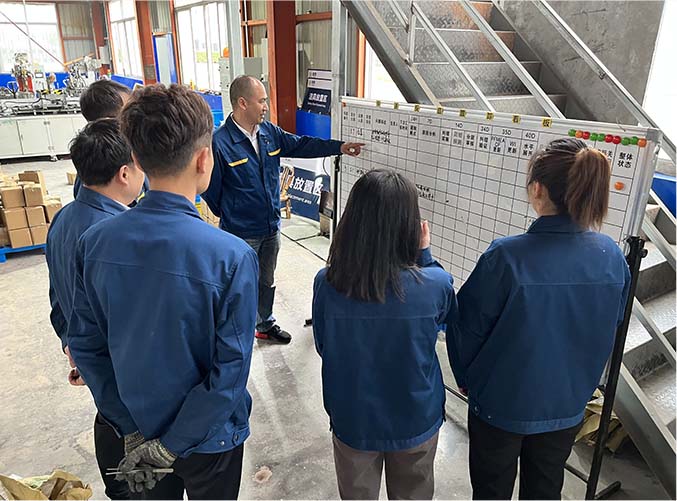

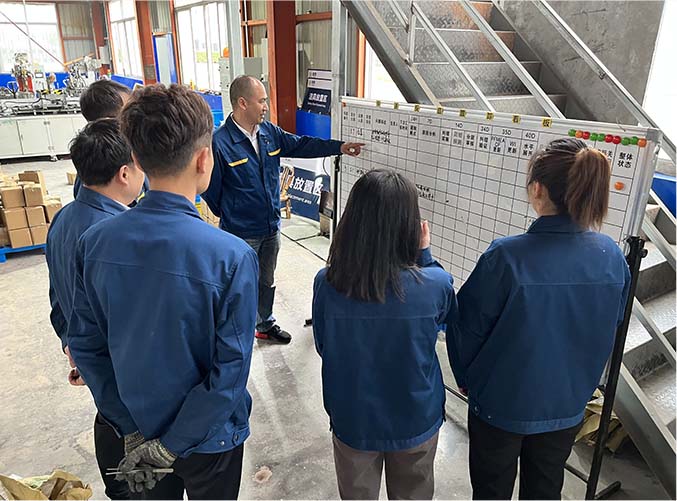

We are a professional team with members boasting extensive years of technical expertise in design and manufacturing. Despite our youthfulness, with an average age of just 31 years, we brim with vitality and an innovative spirit. Dedication is at our core; we firmly believe that customer trust fuels continuous development, and our focus on manufacturing excellence remains unwavering. Above all, we are a team with a shared dream. Hailing from diverse corners of the world, we unite under a common aspiration – to become a truly outstanding precision metal parts company, one that adds significant value to customers through intelligent manufacturing!