CAE Technology Breakthroughs: Pioneering Innovation at the Frontier

INTRODUCTION:

CAE Technology Breakthroughs is a high-profile field in modern manufacturing. The development of this field has revolutionized the way product design and engineering analysis are conducted. At Shaoyi, we are committed to providing high-quality automotive chassis stampings and CNC products, and CAE technology has become a key component of our process excellence. In this blog, we will discuss the characteristics, applications, and innovative use of CAE technology at Shaoyi.

Characteristics of CAE Technology

CAE is a tool that uses computer simulation and analysis to understand and optimize product design and engineering processes. It has the following significant features:

Accuracy:

CAE technology provides highly accurate analyses and predictions , helping engineers better understand the behavior of products under various conditions. This in turn helps reduce the cost of experimentation and trial and error.

Time Savings:

CAE technology can deliver results more quickly than traditional experimentation and testing methods. This accelerates product development cycles , making companies more competitive.

Multi-disciplinary Applications:

CAE technology encompasses a wide range of engineering fields, including structural analysis, fluid dynamics, thermal analysis, and more. This versatility makes it applicable to a widevariety of products and processes.

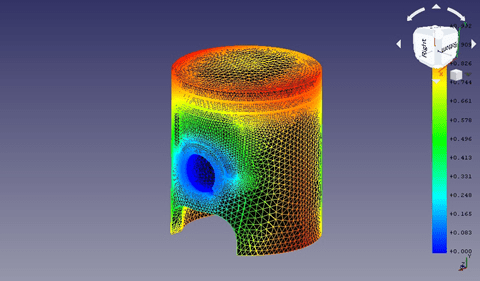

Visualization:

CAE technology can present analysis results through graphics and animations, enabling engineers to gain a visual understanding of product performance and behavior.

Application of CAE Technology

CAE technology is used in a wide range of applications at Shaoyi, affecting product design, engineering analysis, and manufacturing processes. Below are some examples of key areas of application:

Structural Analysis:

In the manufacture of automotive chassis stampings, CAE technology is employed to predict the strength, stiffness, and fatigue life of components. This ensures that the product can withstand the stresses and vibrations encountered under various road conditions.

Fluid Dynamics:

CAE technology plays a key role in optimizing the shape of vehicles and improving aerodynamic performance. By simulating airflow, we can reduce fuel consumption and minimize emissions.

Thermal Analysis:

In automotive manufacturing, thermal analysis of critical components, such as engines and braking systems, is essential. CAE technology aids in predicting temperature distributions, ensuring that these parts operate properly in high-temperature environments.

Material Optimization:

Using CAE technology, we can simulate the properties of different materials so that we can select the most suitable material for a particular application. This helps reduce costs and improve product performance.

Shao Yi’s Innovative Applications

Shaoyi is committed to pushing the limits of CAE technology and is constantly innovating in its applications. Below are some of our breakthroughs in the application of CAE technology:

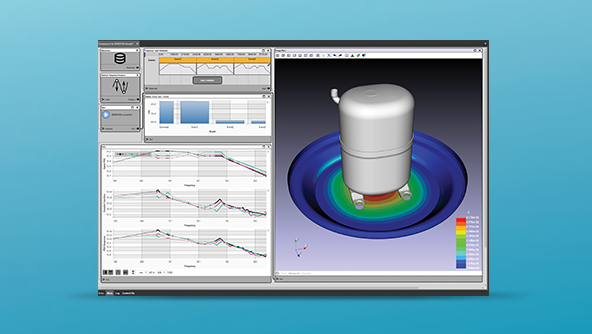

Virtual Prototyping:

We use CAE technology to create virtual prototypes that allow us to test and analyze multiple aspects of a product before actual manufacturing. This virtual prototyping significantly shortens the product development cycle and reduces the cost of manufacturing and testing pilot samples.

Design Optimization:

CAE Technology Breakthroughs allows us to perform multiple design iterations to find the best product design solution. We can perform parametric optimization in a virtual environment to meet different performance and cost objectives.

Failure Simulation:

We use CAE technology to simulate product performance under various extreme conditions to predict possible failures and malfunctions. This helps to identify problems in advance and take steps to fix them, reducing the risk of the product being used in the real world.

Customized Solutions:

Shaoyi is able to provide customized CAE solutions to meet the specific needs of our clients. Our engineers work closely with our customers to ensure that our analysis and simulation meets their unique requirements.

The Future of CAE Technology

In the future, CAE technology will continue to play a key role in driving innovation and competitiveness in the manufacturing industry. Shaoyi will continue to invest in this area to ensure we remain at the forefront of technology. Here are some of our expectations for the future of CAE technology:

More Accurate Simulations:

As computing power continues to improve, we expect to be able to perform more accurate and complex simulations to better understand product performance.

Multi-physical Field Coupling:

CAE technology breakthroughs will increasingly involve the coupling of multi-physical fields, including integrated simulation of structural, fluid, and thermal analyses, in order to more comprehensively assess product performance.

Artificial Intelligence and Machine Learning:

We will explore how Artificial Intelligence and Machine Learning can be applied to CAE techniques to improve model accuracy and speed.

Conclusion

At Shaoyi, CAE technology has become an integral part of our process excellence. It not only improves product quality and performance, but also accelerates product development cycles and reduces costs. Through continuous innovation and investment, we will continue to lead the development of CAE technology to provide customers with high-quality automotive chassis stampings and CNC products. CAE technology is not only a tool, but also an engine to drive innovation in the manufacturing industry, and we look forward to exploring the future of CAE technology with our customers, partners and the industry. Thank you for your trust and support, Shaoyi will continue to actively apply CAE technology to provide excellent solutions for the automotive industry.