Revolutionizing Automotive Manufacturing: Lightweighting Concept with Shao Yi’s Customized Processing

Introduction:

In the dynamic landscape of automotive manufacturing, the pursuit of lightweighting has emerged as a cornerstone of innovation. Shao Yi, a pioneering force in the industry, is at the forefront of revolutionizing automotive design and production. At the heart of our endeavor lies a commitment to customized processing, leveraging the concept of lightweighting to redefine the future of mobility. In this comprehensive blog, we delve into the intricacies of lightweighting and how Shao Yi’s customized processing capabilities are shaping the automotive industry.

1. Lightweighting: The Driving Force of Innovation:

a. Reducing Vehicle Weight:

Lightweighting is the strategic process of reducing the weight of vehicles while maintaining or enhancing performance and safety. By utilizing lightweight materials and optimizing structural designs, automotive manufacturers can achieve significant improvements in fuel efficiency, emissions, and overall vehicle dynamics.

b. Enhancing Efficiency and Sustainability:

Lightweighting plays a pivotal role in enhancing the efficiency and sustainability of automotive systems. Lighter vehicles require less energy to operate, resulting in reduced fuel consumption and lower emissions. Additionally, lightweighting contributes to extended battery life in electric vehicles and facilitates the transition to cleaner, greener transportation solutions.

c. Balancing Performance and Safety:

Despite the focus on weight reduction, lightweighting initiatives prioritize maintaining performance and safety standards. Advanced engineering techniques, such as simulation and testing, ensure that lightweight components meet or exceed regulatory requirements for crashworthiness, durability, and structural integrity.

2. Customized Processing: Empowering Lightweighting Solutions:

a. Tailored Material Selection:

Customized processing empowers automotive manufacturers to select materials tailored to lightweighting objectives. From advanced alloys to composite materials, Shao Yi’s agile manufacturing processes adapt to the unique properties of each material, ensuring optimal weight reduction without compromising performance or durability.

b. Precision Engineering and Design Optimization:

Shao Yi’s customized processing capabilities enable precision engineering and design optimization for lightweighting. Through advanced simulation and prototyping, we refine structural designs to minimize weight while maximizing strength and stiffness, resulting in vehicles that are lighter, more agile, and more fuel-efficient.

c. Integration of Advanced Manufacturing Technologies:

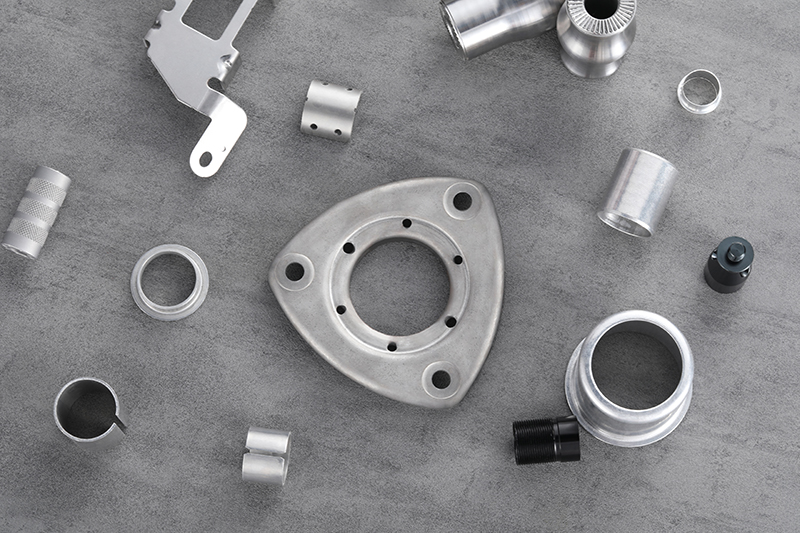

From additive manufacturing to laser cutting and CNC machining, Shao Yi integrates advanced manufacturing technologies to realize lightweighting objectives. These technologies enable intricate geometries, complex shapes, and lightweight structures that were previously unattainable with traditional manufacturing methods.

3. The Impact of Lightweighting on Automotive Components:

a. Body and Chassis:

Lightweighting initiatives impact various automotive components, including body panels, chassis structures, and frame assemblies. By utilizing lightweight materials and innovative design approaches, manufacturers achieve significant weight reductions without compromising structural integrity or safety.

b. Powertrain and Drivetrain:

Lightweighting extends to powertrain and drivetrain components, such as engine blocks, transmission housings, and axle assemblies. Through material optimization and design innovation, manufacturers reduce the weight of these components, improving overall vehicle efficiency and performance.

c. Interior Features and Electronics:

Lightweighting initiatives extend to interior features and electronic systems, including seats, dashboard components, and infotainment systems. By utilizing lightweight materials and advanced manufacturing techniques, manufacturers enhance comfort, convenience, and energy efficiency in vehicle interiors.

4. Future Perspectives and Industry Trends:

a. Advancements in Lightweight Materials:

Shao Yi anticipates advancements in lightweight materials, such as carbon fiber composites, aluminum alloys, and high-strength steels. These materials offer superior strength-to-weight ratios, enabling further weight reductions and performance enhancements in future automotive designs.

b. Integration of Smart Lightweighting Technologies:

The integration of smart lightweighting technologies holds promise for enhancing vehicle efficiency and performance. Shao Yi explores opportunities to incorporate sensors, actuators, and adaptive materials into lightweight components, enabling real-time adjustments and optimizations for varying driving conditions.

c. Collaboration for Sustainable Lightweighting Solutions:

As sustainability becomes a paramount concern, Shao Yi collaborates with industry partners to develop sustainable lightweighting solutions. From recycled materials to bio-based composites, we explore eco-friendly alternatives that minimize environmental impact while achieving weight reduction goals.

5. Conclusion:

In the relentless pursuit of innovation, lightweighting emerges as a transformative force in automotive manufacturing. Shao Yi’s commitment to customized processing empowers lightweighting solutions that redefine the boundaries of performance, efficiency, and sustainability. As we navigate towards a future of mobility, lightweighting remains central to our mission of shaping the automotive industry and driving progress towards cleaner, greener transportation solutions.

Contact Us for More Information:

Interested in exploring lightweighting solutions for your automotive components? Connect with Shao Yi’s team of experts today for personalized consultations and innovative solutions tailored to your needs. Reach out to us at [sales07@nbshaoyi.com] or visit our website at www.shaoyi.com/contact-us. Let’s collaborate to unlock the full potential of lightweighting in automotive manufacturing.