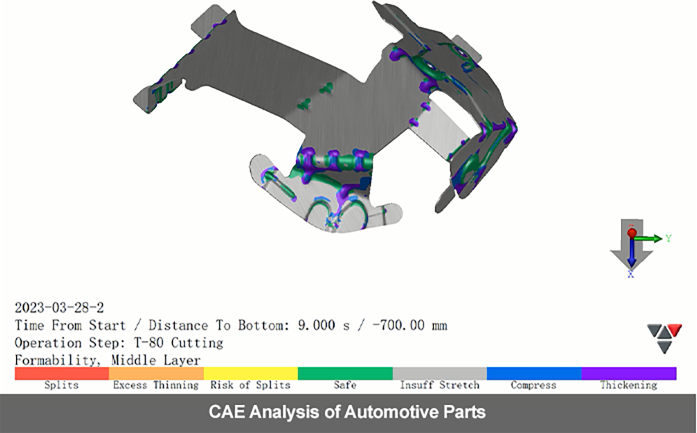

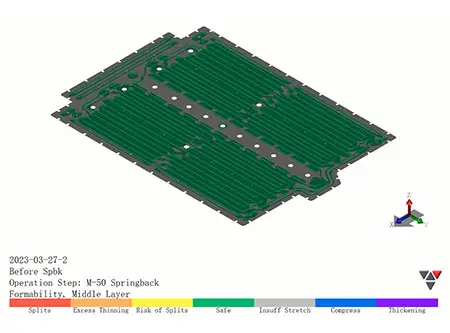

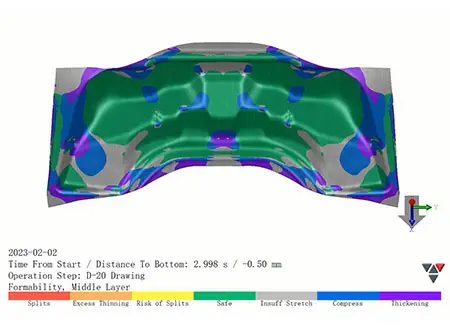

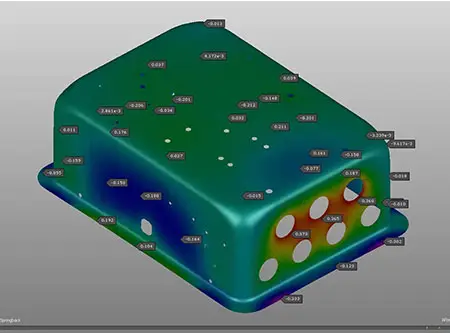

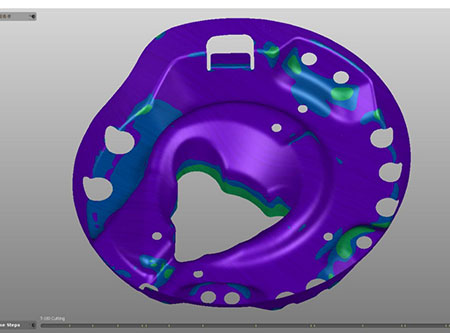

Have you ever pondered the challenges faced in the metal stamping parts industry, especially when dealing with high-strength steel materials boasting yield strengths exceeding 600 MPa? Overcoming rebound issues can indeed be a formidable task! However, we are steadfast in our commitment to finding solutions. This is precisely why we continue to conduct research on the springback phenomenon in stamped parts. Are you curious about the factors influencing the rebound of metal stamping parts for automobiles? Look no further! Our editorial provides insightful information to address your inquiries.

| Processing Capabilities | Processing Capabilities | ||

|---|---|---|---|

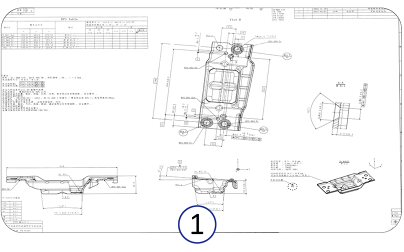

| Maximum part Size | 300mm*200mm*200mm | Perpendicularity | 0.05mm |

| Minimum Part Size | 8mm*6mm*4mm | Oxidize | Film thickness 8-15um |

| Tolerances | 0.02mm | Heat treatment | Hardness 28°-65° |

| Concentricity | 0.05mm | Electrophoresis | Film thickness 15-35um, salt spray test 720h without red rust |

| Roughness | Ra0.8 | Galvanized nickel | Film thickness 8-15um, salt spray test 1500h without red rust |

| Remark |

| zhangasn | Manufacturing Processes and Materials | Manufacturing Processes and Materials | |

|---|---|---|---|

|

CNC Machining Materials

|

Metals

Aluminum Brass Copper Stainless Steel Steel Alloy Steel Mild Low Carbon Titanium |

Pipe Processing

|

steel tube

Carbon tube Alloy pipe stainless steel pipe Aluminum alloy plate 6061 Aluminum 6082 Aluminum 7075 Aluminum |

|

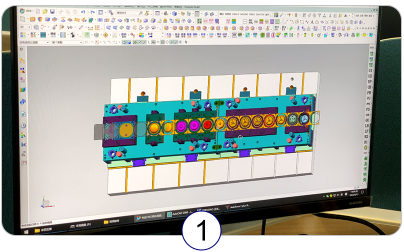

Cold Extrusion

|

steel

Carbon steel Alloy steel stainless steel Aluminum 6061 Aluminum 6082 Aluminum 7075 Aluminum |

After receiving detailed information(your 2D/3D drawings), we will quote you within 12 hours. If the quote is delayed by some reasons, we will notify you.

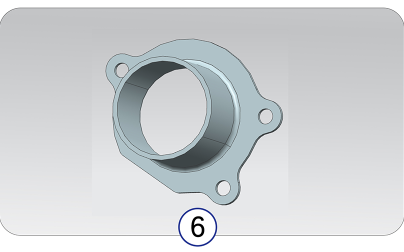

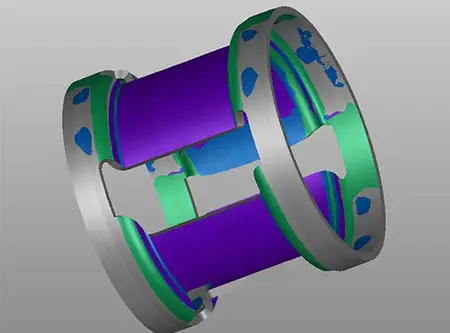

- Various automotive accessories

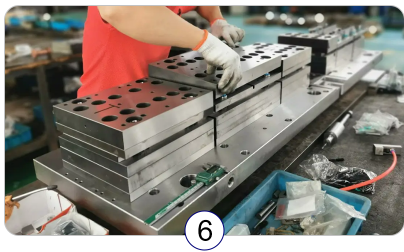

- Over 12 years of experience in mechanical processing

- Achieve strict precision machining and tolerances

- Consistency between quality and process

- Can achieve customized services

- On time delivery