From Tradition to Innovation: Trends in the Die Casting Industry

Introduction:

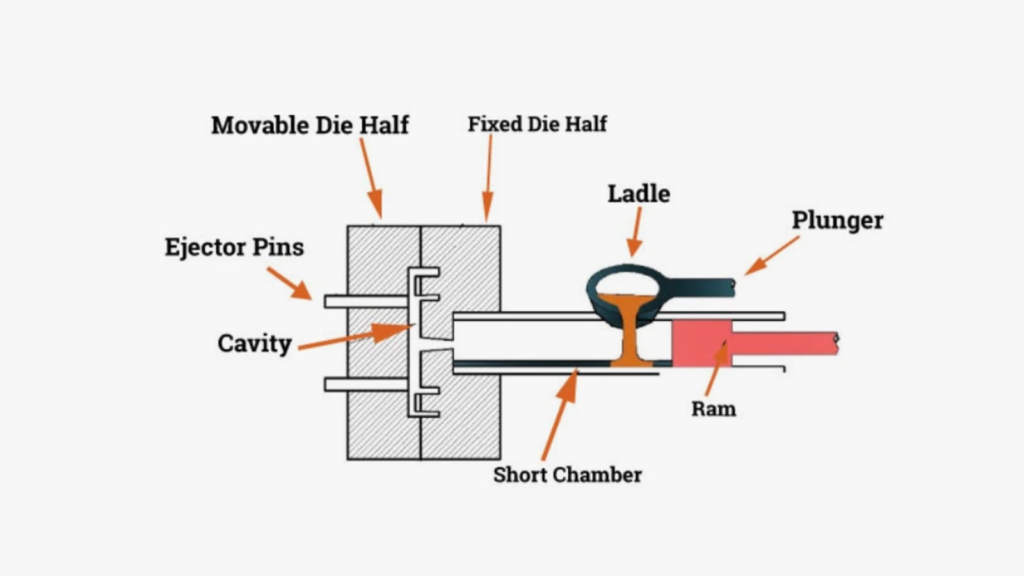

Die Casting Industry:Die casting forces molten metal into molds under high pressure. This technique has evolved over a century. Shaoyi, a precision machining factory, specializes in custom die-casting automotive parts. We use state-of-the-art automation and 100% inspection.

Aluminum Casting Market

The gilobal aluminum casting market was valued at USD 70.4 bilion in 2021 and is projected to reach USD 100.5 bilion by 2026, growing at 7.4% cag!

during the forecast period.

Historical Context: The Roots of Die Casting

Die casting’s origins can be traced back to the invention of the first die casting machine in 1838 by Sturges, which was primarily used for the printing industry. By the early 1900s. The process had expanded into various sectors.Initial materials were tin and lead alloys. Later, zinc, aluminum, and magnesium alloys improved strength, weight, and corrosion resistance.

including automotive and consumer goods, due to its ability to produce complex shapes with high dimensional accuracy and smooth finishes.

Initially, the materials used in die casting were limited to tin and lead alloys. However, the development of zinc, aluminum, and magnesium alloys broadened the scope of applications, making die casting a versatile and indispensable manufacturing process. These materials offered improved strength, lighter weight, and better resistance to corrosion, which were critical for automotive and aerospace industries.

Technological Advancements: Shaping the Future

The aluminum casting market is witnessing considerable growth due to advancement in technology and high efficiency of aluminum cast products.Growina demand in the automobile and consumer apoications, rising miltary investmentin iohtweicht weaponry, and industial expansion in emerainc

economies are the key factors tuelng the growth of the aluminum casting market. These are the key factors driving the demand for aluminum casingduring the forecast period.Due to its appication in passenger cars, motorcycles, aerospace, rains, shipbuilding, commercial vehicles, heavy machinery, building & constructionhardware, power & hand tools, and telecom, aluminium casing has seen substantial expansion in the market. The need for ightweight cars and otheivehicles is arowing along with new sectors, which is opening up opportuniies for the aluminium casting market. The ongoing growth of manufacturingfaclities across all industries in the nation is being driven by economic development coupled with the cheap supply of labour and raw materials.particularly in China.

High-Pressure Die Casting (HPDC)

One of the most significant advancements in die casting technology is high-pressure die casting. HPDC allows for the production of components with thinner walls and more intricate designs, which are essential for modern applications requiring lightweight and high-strength parts. HPDC produces components with thinner walls and intricate designs. It enables faster production cycles and improved surface finishes.

Vacuum Die Casting

Vacuum die casting is another innovation that has improved the quality of die-cast parts. By reducing the air entrapment in the mold cavity, this technique minimizes porosity and enhances the mechanical properties of the cast components. This is particularly beneficial for industries where structural integrity is paramount, such as automotive and aerospace.

Squeeze Casting

Combining the advantages of both casting and forging, squeeze casting is a process where molten metal is poured into a preheated die and subjected to high pressure. This results in components with excellent mechanical properties and minimal porosity, making it ideal for high-strength applications.

Automation and Robotics

The integration of automation and robotics has revolutionized the die casting industry. Automated systems can handle repetitive tasks with high precision and consistency, reducing labor costs and minimizing human error. Robots are used for tasks such as die spraying, part extraction, and finishing operations, improving overall efficiency and productivity.

Simulation and Modeling

Advanced simulation and modeling software have become indispensable tools in die casting. These tools allow engineers to design and optimize molds, predict potential defects, and simulate the entire casting process before actual production. This reduces the time and cost associated with trial-and-error methods and enhances the quality of the final product.

Material Innovations: Expanding Horizons

Advanced Aluminum Alloys

Recent developments in aluminum alloys improve strength, ductility, and corrosion resistance. These alloys are crucial for automotive and aerospace applications.

Magnesium Alloys

Magnesium alloys are lightweight with an excellent strength-to-weight ratio. Innovations have made them more robust and easier to cast.

Zinc Alloys

Zinc alloys offer excellent fluidity for intricate details. Improved mechanical properties make them suitable for demanding applications.

Composite Materials

Composite materials embed fibers or particles into the metal matrix. They offer superior strength, stiffness, and wear resistance.

Industry Applications: Driving Demand

Automotive Industry

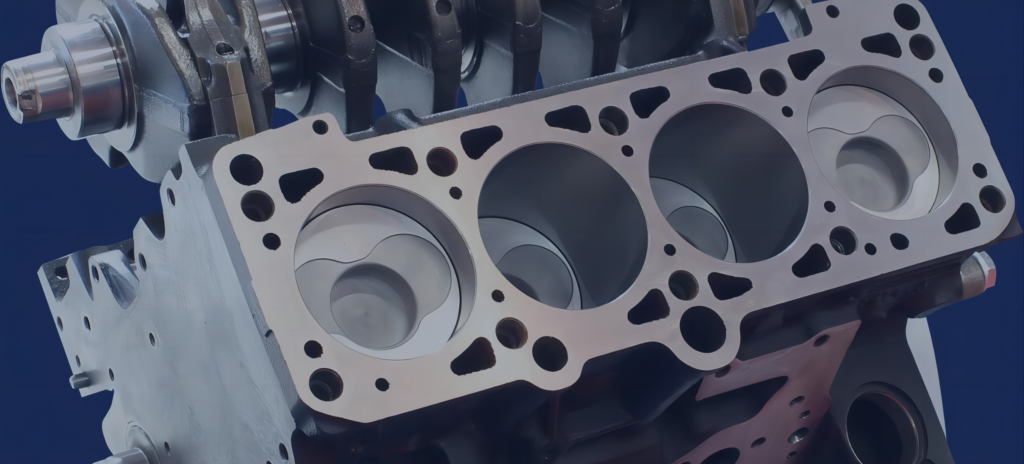

The automotive industry is one of the largest consumers of die-cast components. The demand for lightweight, fuel-efficient vehicles has driven the adoption of aluminum and magnesium die castings for engine parts, transmission cases, and structural components. Additionally, the rise of electric vehicles (EVs) has spurred the need for die-cast parts in battery housings and motor casings.

Aerospace Industry

In aerospace, weight reduction is critical for improving fuel efficiency and payload capacity. Advanced die casting techniques and materials have enabled the production of lightweight, high-strength components for aircraft structures, engine parts, and landing gear. The ability to produce complex shapes with high precision is particularly valuable in this sector.

Consumer Electronics

The miniaturization trend in consumer electronics has increased the demand for die-cast components. Magnesium and aluminum die castings are used for enclosures, frames, and heat sinks in smartphones, laptops, and other electronic devices. The excellent thermal conductivity of these materials helps in efficient heat dissipation, ensuring the reliability and performance of electronic products.

Medical Devices

Die casting plays a vital role in the medical device industry, where precision and reliability are paramount. Components such as surgical instruments, imaging equipment housings, and implantable devices benefit from the high dimensional accuracy and biocompatibility of die-cast materials. The ability to produce complex geometries with smooth finishes is crucial for medical applications.

Renewable Energy

The renewable energy sector, including wind, solar, and hydroelectric power, requires robust and durable components. Die-cast parts are used in wind turbine housings, solar panel frames, and hydroelectric generator components. The development of corrosion-resistant and high-strength alloys has enhanced the performance and longevity of these components in harsh environments.

Shaoyi’s Role in the Die Casting Industry

Shaoyi pushes die casting boundaries with advanced automation. Our 100% inspection process ensures high-quality production. We specialize in custom automotive parts, leveraging the latest technology.

Our factory is equipped with cutting-edge machinery and a highly skilled workforce, allowing us to handle complex projects with precision and efficiency. We utilize advanced simulation and modeling software to optimize our mold designs and predict potential issues before production begins. This proactive approach minimizes defects and enhances the overall quality of our products.

Sustainability and Environmental Considerations

Recycling and Reusability

Die casting is inherently a sustainable manufacturing process due to the high recyclability of metals such as aluminum and zinc. Scrap metal generated during the process can be collected and reused, reducing waste and conserving raw materials. This closed-loop recycling system aligns with the principles of a circular economy.

Energy Efficiency

Modern die casting techniques and equipment are designed to minimize energy consumption. The use of electric and hybrid furnaces, along with efficient melting and casting processes, has significantly reduced the carbon footprint of die casting operations. Additionally, advanced insulation materials and heat recovery systems further enhance energy efficiency.

Eco-Friendly Alloys

The development of eco-friendly alloys with reduced environmental impact is a growing trend. These alloys are designed to minimize the use of hazardous elements and promote the use of sustainable raw materials. For example, some aluminum alloys now contain recycled content, reducing the demand for virgin material and associated environmental impact.

Emission Control

Emission control measures, such as the use of clean fuels and advanced filtration systems, have been implemented to reduce the release of pollutants during the die casting process. These measures help in meeting stringent environmental regulations and improving the overall sustainability of the industry.

Future Directions: Embracing Innovation

Additive Manufacturing Integration

The integration of additive manufacturing (AM) with die casting presents exciting possibilities. AM can be used to create complex mold inserts and cores, enhancing the flexibility and precision of the die casting process. This hybrid approach combines the strengths of both technologies, enabling the production of intricate and high-performance components.

Smart Manufacturing

The adoption of Industry 4.0 principles, including the Internet of Things (IoT), artificial intelligence (AI), and big data analytics, is transforming the die casting industry. Smart manufacturing systems can monitor and control the entire casting process in real-time, optimizing parameters, predicting defects, and ensuring consistent quality. This data-driven approach enhances productivity and reduces downtime.

Advanced Surface Treatments

Ongoing research into new alloy compositions aims to push the boundaries of die casting materials. These new alloys are designed to offer superior mechanical properties, better castability, and enhanced sustainability. For example, high-entropy alloys and superalloys are being investigated for their potential in extreme environments and high-performance applications.

New Alloy Development

Research into new alloys pushes material boundaries. High-entropy and superalloys offer superior properties for extreme environments.

Collaborative Innovations

Industry, academia, and research institutions drive die casting innovation. Collaborative R&D efforts lead to breakthroughs in materials and technologies.

Conclusion:

Die casting has evolved through technological advancements and material innovations. Shaoyi leads this evolution with advanced automation and 100% inspection, ensuring high-quality custom automotive parts. As the industry embraces new technologies and sustainability, Shaoyi remains committed to delivering excellence.

Request for Quote (RFQ) Information

If you are interested in Shaoyi’s custom die-casting services, please provide the following Your company’s contact details, including the primary point of contact.

Any additional notes or special instructions for your project.

Shaoyi(Ningbo)Metal Technology Co.,Ltd

Phone: +86-19817255737

Email:sales07@nbshaoyi.com

Website: www.nbshaoyi .com

FAQ:

What makes Shaoyi’s die casting services unique?

Shaoyi offers state-of-the-art automation, 100% inspection, and custom automotive parts production. Our advanced technology ensures precision and quality.

How does Shaoyi ensure the quality of its die-cast products?

We utilize advanced simulation, modeling software, and a 100% inspection process. This guarantees each part meets our stringent quality standards.

What industries does Shaoyi serve?

Shaoyi specializes in automotive parts but also serves aerospace, consumer electronics, medical devices, and renewable energy sectors.