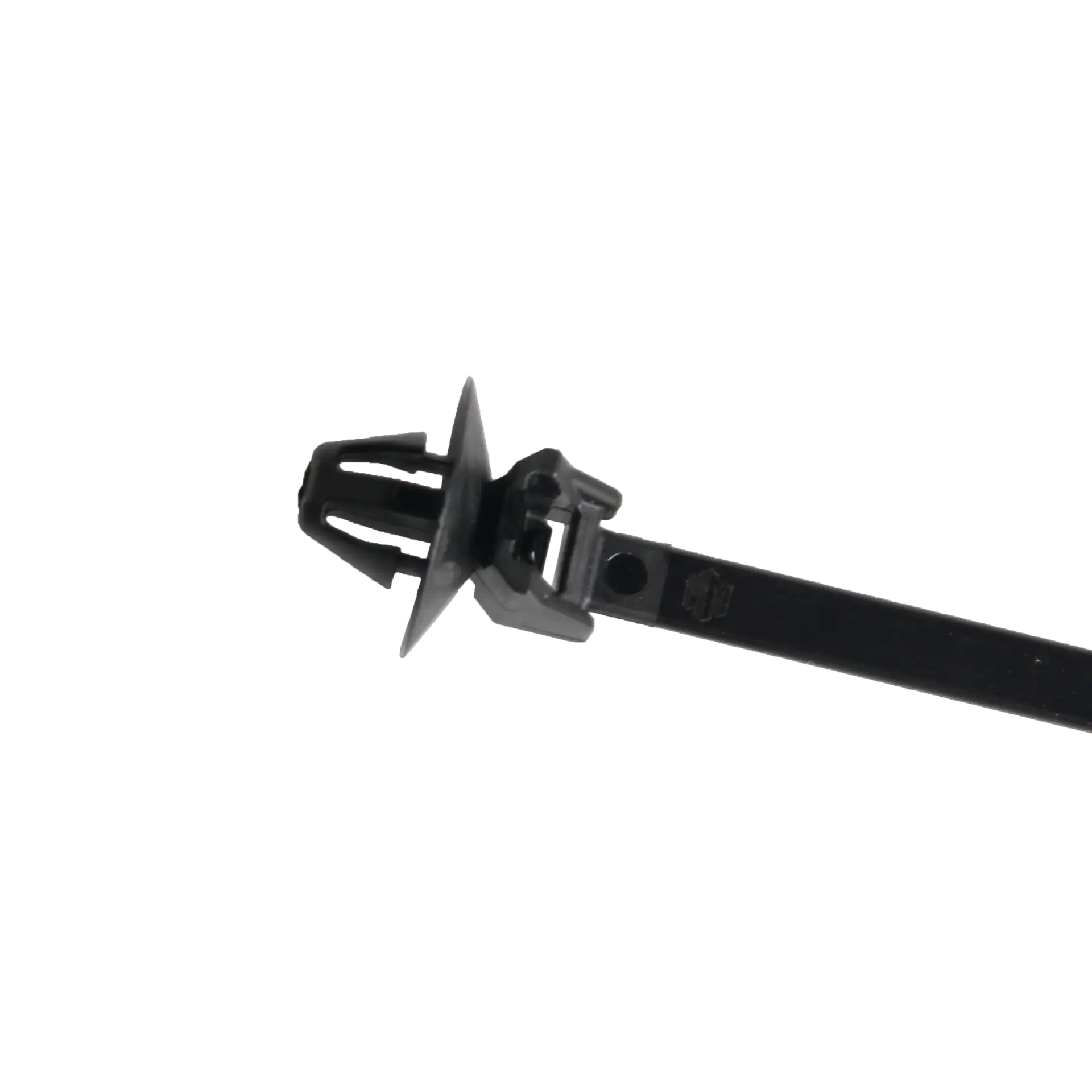

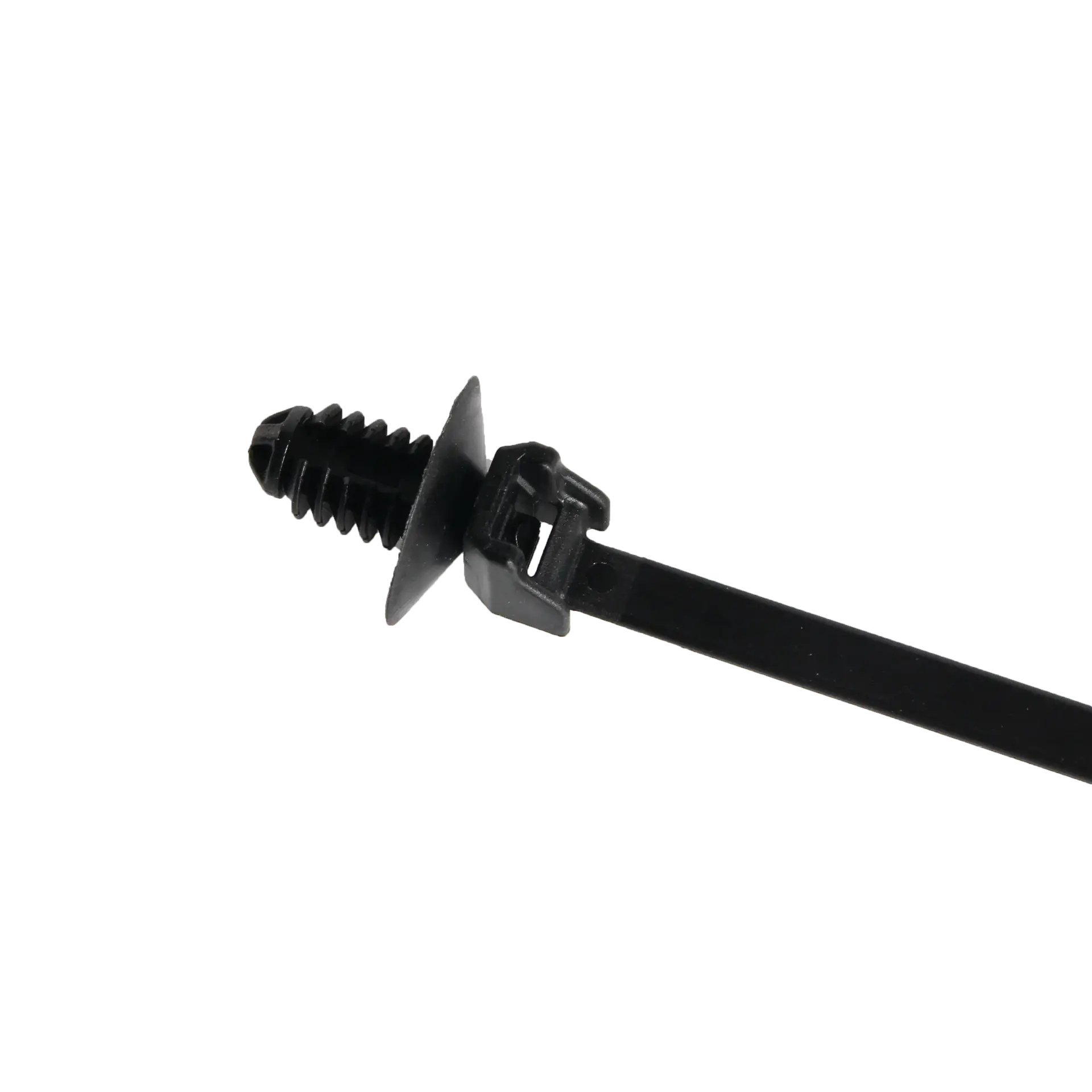

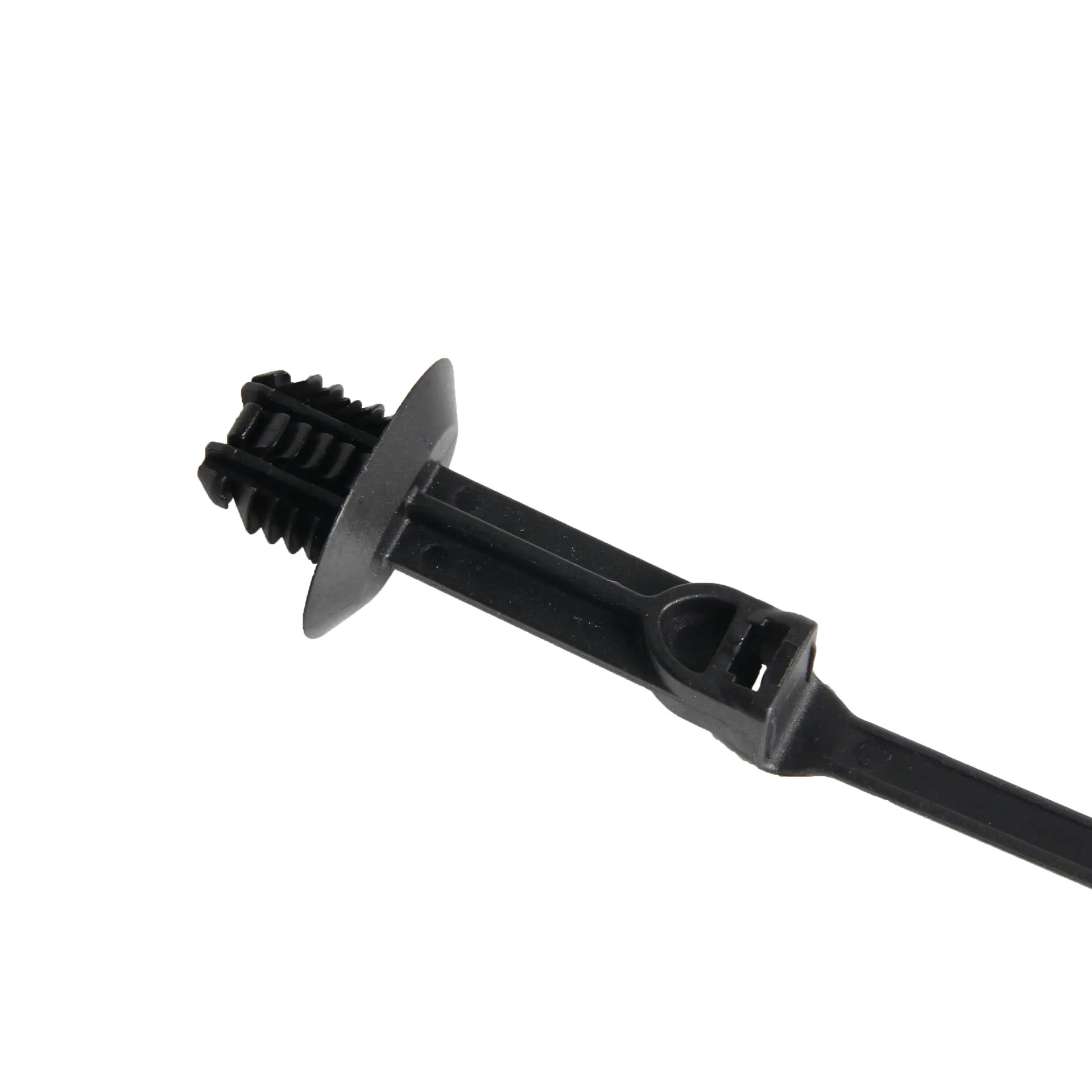

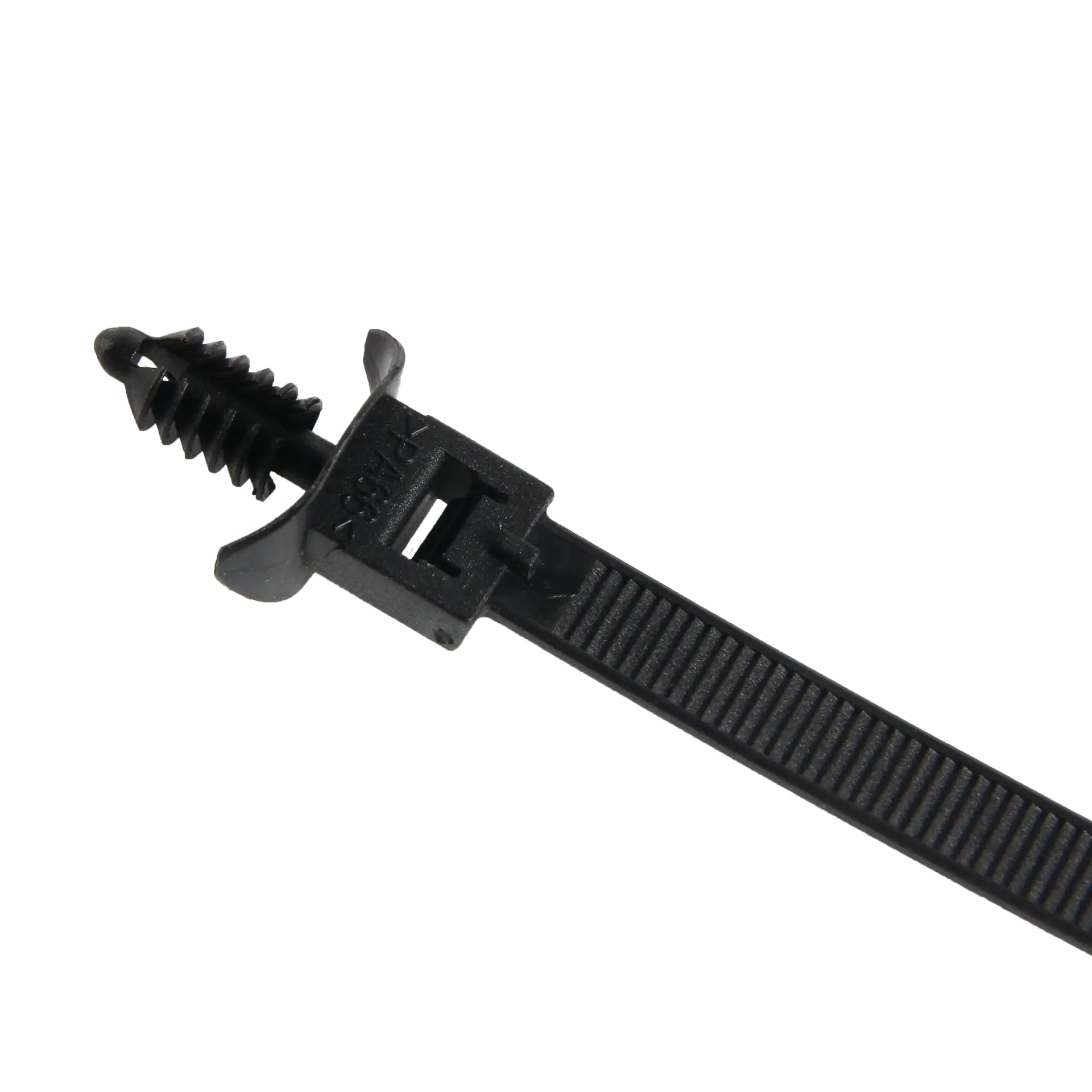

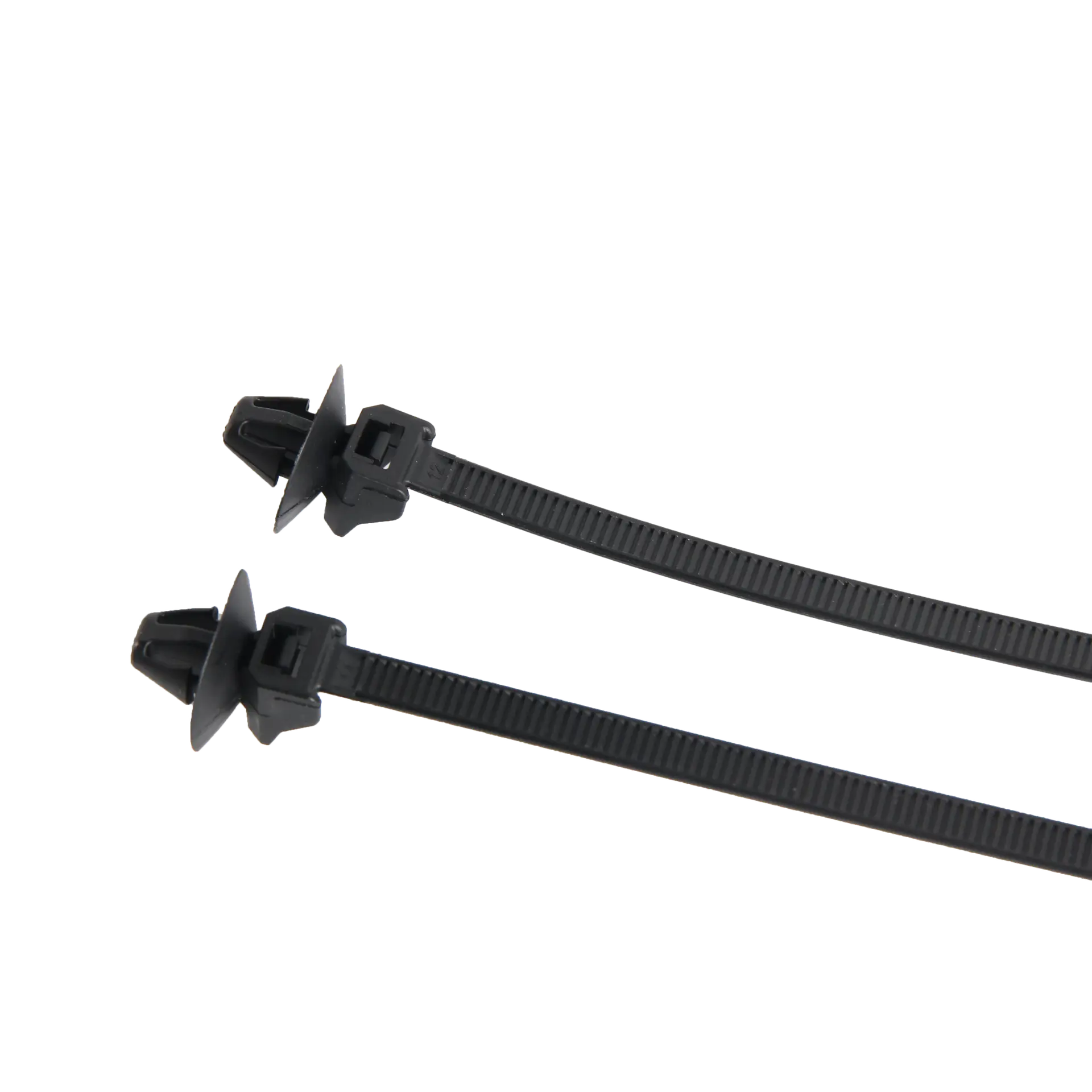

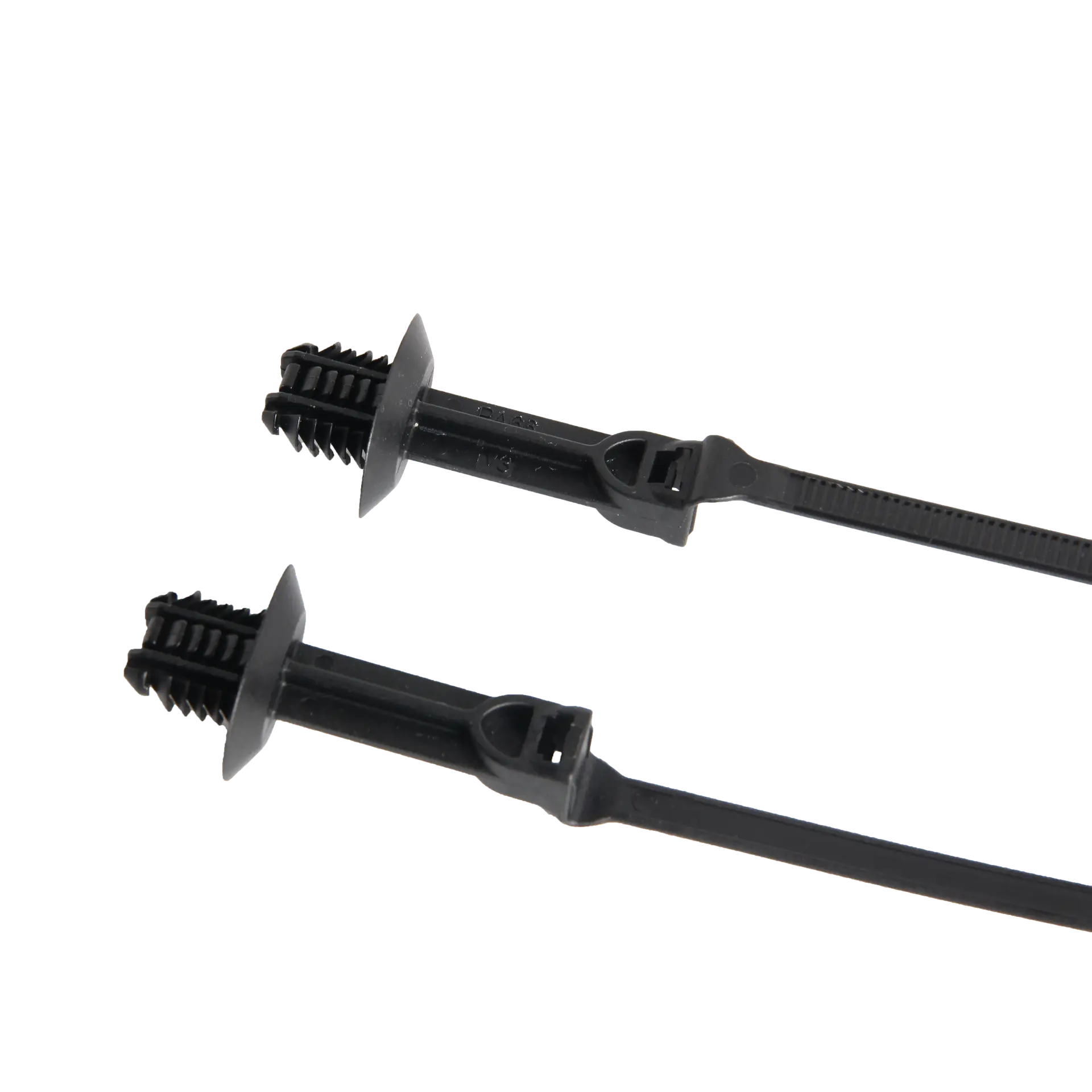

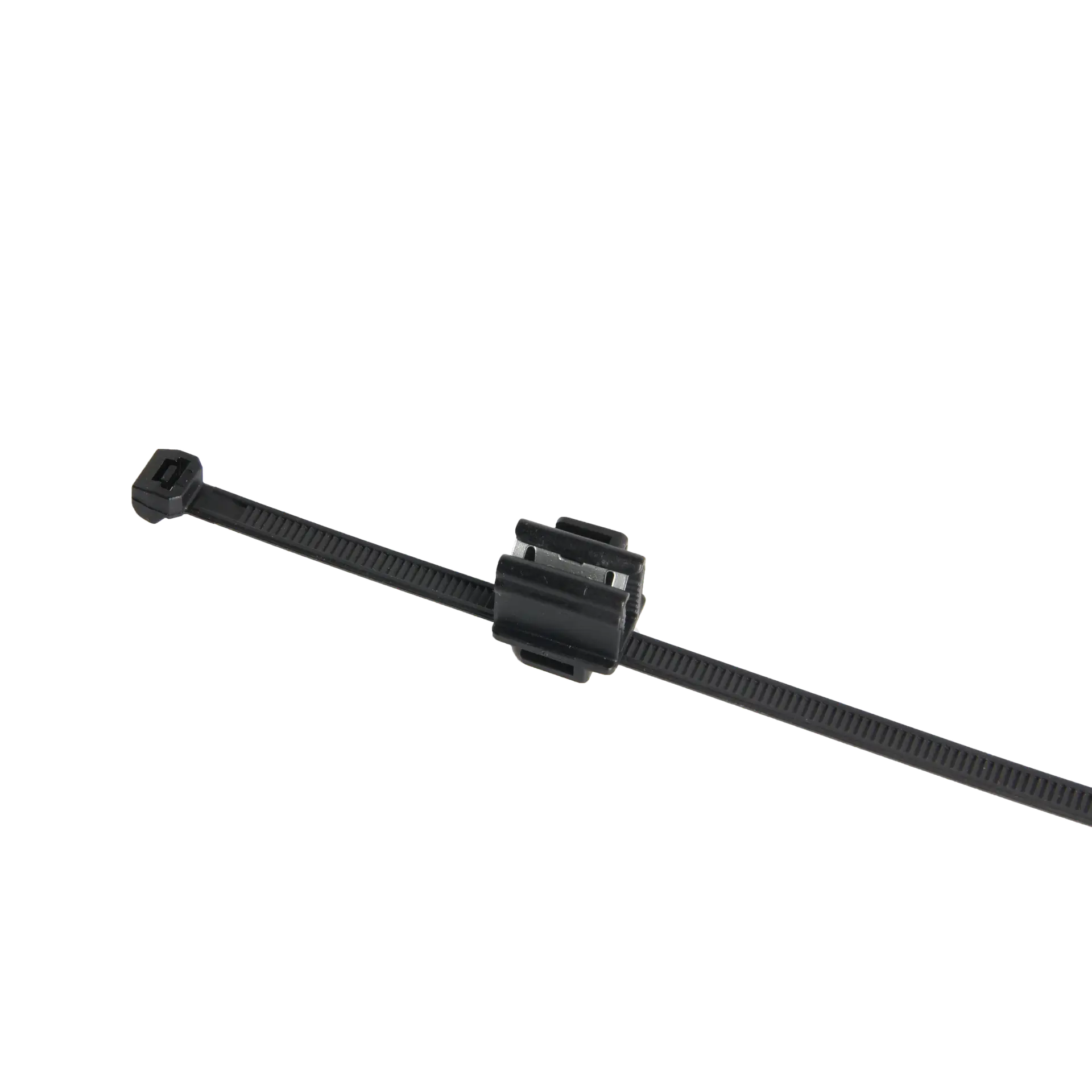

Automotive Cable Tie

With 15 years of experience in customized processing of automotive zip ties, we have rich professional knowledge throughout the entire process chain of automotive zip ties. Operating within our technology center, we are committed to sharing our knowledge with you, assisting in process improvement, and establishing automotive ties as the preferred method for automotive component parts.

UPLOAD A PART >>

SAMPLE DESIGN ANALYSIS >>

Certificate

IATF TS16949:2016/Critical to Quality

55 million

Parts finished each month

15+

R&D Engineer

20+

Steel & Aluminum

Metal Stampings For Automotive

Project Management Process

Requirement input (drawing. standard technical requirement)

1

Quotation

2

Starting

3

Products planning (CAE analyse,prem-inary planning)

4

Products design (sample –softmold -DV)

5

Products design (sample –softmold -DV)

6

Product validation

7

Sample(PV-PPAP)

8

2TP

9

OTS

10

Production Advantages

Automated Production

Our cable ties are manufactured through fully automated injection molding processes, ensuring high efficiency and consistent quality. With advanced automation, we can meet large-volume production demands while maintaining precision and reducing lead times. This automation helps us deliver reliable, cost-effective solutions for our customers.

Personalized Customization

We have a professional R&D team with over 10 years of experience in the automotive industry. Our expertise enables us to assist customers in the initial development of automotive injection molded products and provide tailored solutions to meet their needs and challenges.

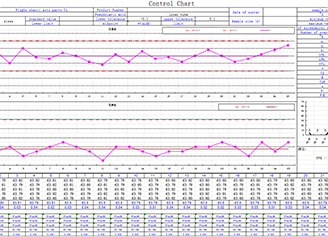

100% Quality Inspection

Our company has a complete quality control system, which is controlled through QC reports throughout the entire production process. We have advanced equipment such as size testing, chemical composition analysis, non-destructive testing, and so on.

80N Binding Force

Using fine materials,binding force of 8oN,and other products on the market is only 40-50N,with high strength bundling is not easy to slack off.

Production Workshop

Automatic Inspection

Automatic Workshop

Cable Tie Automatic Assembly Workshop

EDM (Spark Machine)

Injection workshop

Mold Assembly Workshop

Mold Warehouse

Raw Material Warehouse

Inspection Personnel

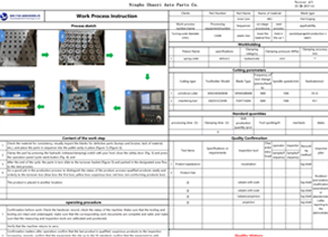

Eight Core Processes Only In Pursuit Of Achieving Sub-2000 Dppm Efforts

Standardized,process-oriented refined production standards efforts to provide you with up to 99.8%qualified string of precision parts

Processing Capabilities

| Processing Capabilities | Remark | ||

|---|---|---|---|

| Origin | China | Colour | The standard color is (black/natural) and other colors can be customized if needed

authentication UR |

| Apply | Fixed bundling | Packing | The quantity of inner packaging small packages is PCS100/500/1000, and the size of the outer packaging cardboard box is 430mm * 330mm * 300mm. According to the length of the product, it is 3000PCS/4000PCS/6000PCS/8000PCS/10000PCS respectively |

| Tensile strength | 180N-260N | Bundle diameter | 3mm-80mm |

| Material | PA66 | Working temperature | -40-150 |

| Tensile strength | 180N-260N | Features | Convenient, fast bundling, stable fixation |

| Certificate | ROHS2.0 | Usage | Fixed and tightened |

| Application scope | Fixation of wiring harnesses for automobiles, high-speed trains, and ships, as well as various equipment, household appliances, new energy, and other scenarios | Delivery time | 15-30 (working days) |

Surface Treatment

Phosphating

Blackening

Electrophoresis

Powder Coating

Baking Pain

Galvanizing

Copper Plating

Galvanized Nickel Alloy

Spray Painting

Dacromet Coating

Our Manufacturing Services

Focus on chassis welded assemblies, shock-absorbing welded assemblies, chassis stamping, and machining parts.

Frequently Asked Questions

How many years of experience do we have in the processing of automotive components? Our products cover suspension,shock absorption, and other systems in automobiles, providing services to global brands

After receiving detailed information(your 2D/3D drawings), we will quote you within 12 hours. If the quote is delayed by some reasons, we will notify you.

Contact Us

Complete control over products allows us to ensure our customers receive the best quality prices and

service

INQUIRY FORM

After years of devepopment, the company's welding technology mainnly includes gas shielded welding,

arc welding, laser welding and kinds of welding technologies, combined with automatic assemble

lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT)

Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high

capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick

quotation to provide customers with better service for chassis stamping parts and maching parts.

- Various automotive accessories

- Over 12 years of experience in mechanical processing

- Achieve strict precision machining and tolerances

- Consistency between quality and process

- Can achieve customized services

- On time delivery