AUTOMOTIVE DIE CASTING

With 15 years of machining experience, we possess extensive expertise across the entire process chain of die-cast structural components. Operating within our technology center, we are committed to sharing our knowledge with you, aiding in process enhancement, and establishing die-casting as the preferred method for structural components.

UPLOAD A PART >>

SAMPLE DESIGN ANALYSIS >>

Certificate

IATF TS16949:2016/Critical to Quality

55 million

Parts finished each month

15+

R&D Engineer

20+

Steel & Aluminum

Die casting for automobiles

Types of parts for automobiles

Powertrain Suspension Components

Chassis Parts

Body Parts

New Energy Battery&Motor Housings

Metal Stampings For Automotive

Project Management Process

Requirement input (drawing. standard technical requirement)

1

Quotation

2

Starting

3

Products planning (CAE analyse,prem-inary planning)

4

Products design (sample –softmold -DV)

5

Products design (sample –softmold -DV)

6

Product validation

7

Sample(PV-PPAP)

8

2TP

9

OTS

10

Production Advantages

Automated Production

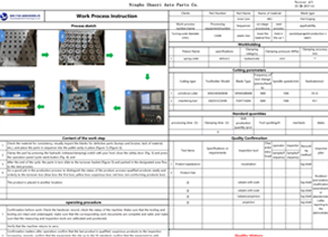

We building automated production and testing production lines.Introducing highly automated equipment to improve efficiency and ensure product consistency.We building automated production and testing production lines.Introducing highly automated equipment to improve efficiency and ensure product consistency.

Personalized Customization

The R&D technical team consists of over 20 people. The average age is 33 years old.We prioritize stringent standards meeting high-quality demands, and fostering innovation for diverse automotive needs.

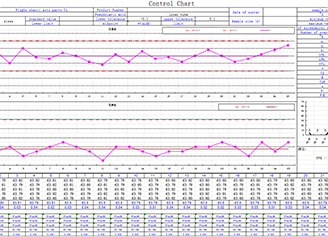

100% Quality Inspection

Our company has a complete quality control system, which is controlled through QC reports throughout the entire production process.We have advanced equipment such as size testing chemical composition analysis,non-destructive testing, etc.

One-stop Service

We provide one-stop services for all customers,having multiple processes, including die-casting, CNC ,automated welding, surface treatment, mold manufacturing, laser cutting, and stamping.

Production workshop

Aluminum Dross Removal and Degassing Machine

Automatic Powder Coating Assembly Line

Die Casting Trim Press

Die Casting Workshop

Electrophoretic Coating Production Line

Machining Workshop

Mold Area

Quality Inspection Laboratory

Inspection Personnel

Eight Core Processes Only In Pursuit Of Achieving Sub-2000 Dppm Efforts

Standardized,process-oriented refined production standards efforts to provide you with up to 99.8%qualified string of precision parts

Processing Capabilities

| Processing Capabilities | Remark | ||

|---|---|---|---|

| Surface Treatment | Polishing agent, powder coating, paint coating, electronic coating, sandblasting, shot blasting, anodizing

Polishing + galvanizing/chromium plating/pearl chrome/nickel plating/steel plating |

Stamping Maximum Part Size | |

| Heat Treatment | T1-T5 | Stamping Minimum Part Size | |

| Maximum Part Size | Maximum width up to 500mm, maximum thickness T up to 80mm | ||

| Minimum Part Size | Minimum width of 10mm, minimum thickness T of 1.0mm | ||

| Tolerance | 0.02MM; 100% QC quality inspection before shipment, quality inspection report available | ||

| Product Standards | Material standard EN 1706, Porosity standard ASTM E505 | ||

| Annual Supply Capacity | 100 million | ||

| Processing Capability | Tapping, milling, grinding, drilling, CNC machining |

Surface Treatment

Phosphating

Blackening

Electrophoresis

Powder Coating

Baking Pain

Galvanizing

Copper Plating

Galvanized Nickel Alloy

Spray Painting

Dacromet Coating

Our Manufacturing Services

Focus on chassis welded assemblies, shock-absorbing welded assemblies, chassis stamping, and machining parts.

Frequently Asked Questions

How many years of experience do we have in the processing of automotive components? Our products cover suspension,shock absorption, and other systems in automobiles, providing services to global brands

After receiving detailed information(your 2D/3D drawings), we will quote you within 12 hours. If the quote is delayed by some reasons, we will notify you.

Contact Us

Complete control over products allows us to ensure our customers receive the best quality prices and

service

INQUIRY FORM

After years of devepopment, the company's welding technology mainnly includes gas shielded welding,

arc welding, laser welding and kinds of welding technologies, combined with automatic assemble

lines, through Ultrasonic Testing (UT), Radiographic Testing(RT), Magnetic particle Testing(MT)

Penetrant Testing(PT), Eddy Current Testing(ET), Pull-off force of testing, to achieve high

capacity, high quality and safer welding assemblies, we could supply CAE, MOLDING and 24-hour quick

quotation to provide customers with better service for chassis stamping parts and maching parts.

- Various automotive accessories

- Over 12 years of experience in mechanical processing

- Achieve strict precision machining and tolerances

- Consistency between quality and process

- Can achieve customized services

- On time delivery