Automotive Engine Component Manufacturing: Machining Processes and Quality Control Insights at Shaoyi Company

Introduction:

Automotive engine components form the heart of a vehicle, playing a critical role in its performance, efficiency, and reliability. At Shaoyi Company, we understand the importance of precision manufacturing and stringent quality control in producing engine parts that meet the highest standards of excellence. In this blog, we delve into the intricacies of machining processes and quality control measures employed by Shaoyi Company in the production of automotive engine components, highlighting our strengths and commitment to delivering superior products.

Machining Processes for Automotive Engine Components:

The manufacturing of automotive engine components requires a blend of advanced machining processes and technical expertise to achieve the desired specifications and performance characteristics. At Shaoyi Company, we employ a variety of machining techniques tailored to the specific requirements of each component, including:

1.Turning and Milling:

Turning and milling are fundamental machining processes used to shape raw materials into precise components with complex geometries. Shaoyi Company utilizes state-of-the-art CNC turning and milling machines to fabricate engine parts such as pistons, crankshafts, camshafts, and cylinder heads with exceptional accuracy and surface finish.

2.Grinding and Honing:

Grinding and honing processes are employed to achieve tight tolerances and surface finish requirements for critical engine components. Shaoyi Company’s advanced grinding and honing capabilities enable us to refine the dimensional accuracy and surface quality of components like cylinder liners, valve seats, and connecting rods to meet exacting specifications.

3.Drilling and Tapping:

Drilling and tapping operations are essential for creating holes, threads, and other features in engine components. Shaoyi Company utilizes high-speed drilling and tapping machines equipped with advanced tooling to ensure precise hole placement, size, and thread integrity in components such as engine blocks, cylinder heads, and intake manifolds.

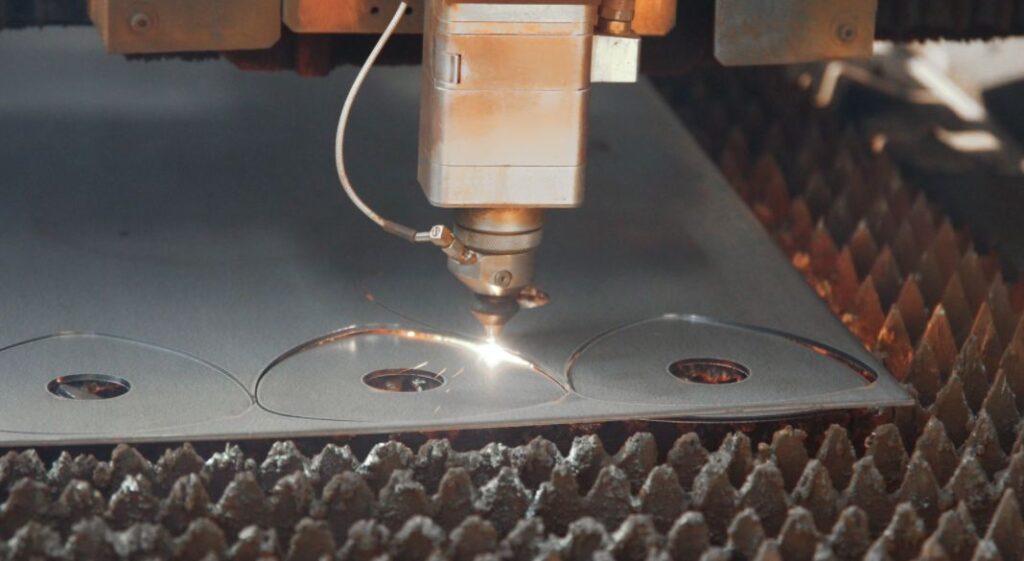

4.Laser Cutting and Welding:

Laser cutting and welding technologies are employed for precision cutting, shaping, and joining of materials in engine component fabrication. Shaoyi Company’s expertise in laser cutting and welding allows us to produce intricate features and assemblies in components such as exhaust manifolds, turbocharger housings, and fuel injection systems with exceptional precision and reliability.

Quality Control Measures in Engine Component Manufacturing:

Ensuring the quality and reliability of automotive engine components is paramount to Shaoyi Company’s commitment to excellence. We employ rigorous quality control measures throughout the manufacturing process to uphold the highest standards of quality and performance, including:

1.Material Inspection:

Before machining begins, raw materials undergo thorough inspection to verify their composition, mechanical properties, and dimensional accuracy. Shaoyi Company works closely with trusted material suppliers to source high-quality materials that meet or exceed industry standards.

2.In-Process Monitoring:

Throughout the machining process, our skilled technicians utilize advanced metrology equipment to monitor critical dimensions, surface finish, and geometric tolerances in real-time. Any deviations from specified parameters are promptly identified and addressed to ensure conformance to design requirements.

3.Final Inspection and Testing:

Upon completion of machining operations, finished components undergo comprehensive inspection and testing to validate their dimensional accuracy, surface quality, and functional performance. Shaoyi Company employs a range of inspection techniques, including coordinate measuring machines (CMM), optical inspection systems, and functional testing rigs, to verify compliance with customer specifications and industry standards.

4.Traceability and Documentation:

Shaoyi Company maintains meticulous records of all manufacturing processes, inspection results, and quality assurance activities for each engine component produced. This ensures full traceability and accountability throughout the product lifecycle and facilitates continuous improvement initiatives to enhance product quality and customer satisfaction.

FAQs:Automotive Engine Component Manufacturing at Shaoyi

1. What are the key machining processes used in the production of automotive engine components at Shaoyi Company?

At Shaoyi Company, we utilize a range of advanced machining processes tailored to the specific requirements of each engine component. These include turning and milling, grinding and honing, drilling and tapping, as well as laser cutting and welding. These processes enable us to fabricate engine parts with exceptional precision and surface finish.

2. How does Shaoyi Company ensure the quality of automotive engine components during the manufacturing process?

Quality control is a top priority at Shaoyi Company. We employ rigorous quality control measures throughout the manufacturing process, including material inspection, in-process monitoring, final inspection and testing, as well as traceability and documentation. These measures ensure that our engine components meet the highest standards of quality and performance.

3. How does Shaoyi Company ensure precision and accuracy in the machining of engine components?

Precision and accuracy are achieved through a combination of state-of-the-art CNC machining equipment, skilled technicians, and meticulous process control. Our CNC machining processes are programmed to exact specifications, and our technicians closely monitor machining operations to ensure that critical dimensions and tolerances are maintained throughout the production process.

4. Can Shaoyi Company accommodate custom or prototype engine component manufacturing projects?

Yes, Shaoyi Company has extensive experience in custom and prototype manufacturing of engine components. Our team of engineers and technicians works closely with clients to understand their specific requirements and develop tailored solutions to meet their needs. Whether it’s a one-off prototype or a high-volume production run, we have the capabilities to deliver precision-engineered engine components on time and within budget.

5. What quality assurance certifications does Shaoyi Company hold for automotive engine component manufacturing?

Shaoyi Company is committed to upholding the highest standards of quality and compliance. We are ISO 9001 certified, demonstrating our commitment to quality management systems and continuous improvement. Additionally, we adhere to industry-specific quality standards and customer requirements to ensure that our engine components meet or exceed expectations.

Contact Us:

To learn more about Shaoyi Company’s capabilities in automotive engine component manufacturing and how we can support your project requirements, please contact us:

Shaoyi(Ningbo)Metal Technology Co.,Ltd

Phone: +86-19817255737

Email:sales07@nbshaoyi.com

Website: www.nbshaoyi .com