Shaoyi’s Innovation and Application of Welding Technology in the Automotive Industry

Introduction:

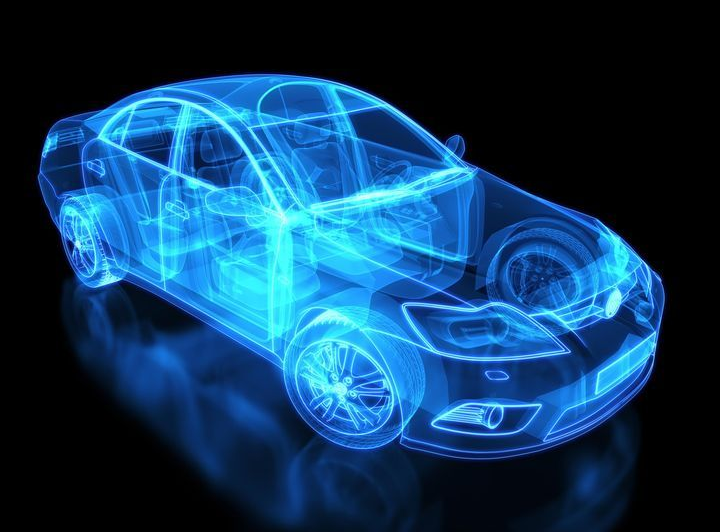

Welding technology plays a crucial role in today’s automotive industry, driving continuous development and innovation. Through precise welding techniques, automotive manufacturers ensure the structural integrity and safety of vehicles, providing reliable protection for passengers. Additionally, welding processes facilitate the realization of lightweight vehicle designs by effectively joining automotive components. Moreover,reducing production costs and increasing manufacturers’ competitiveness. In summary, welding technology in the automotive industry is not just a technical means ,laying a solid foundation for creating a safer and environmentally friendly automotive future.

The Role of Welding Technology in the Automotive Industry 4.0 Era

In the Automotive Industry 4.0 era, welding technology plays a pivotal role in driving innovation and transformation. With the advent of advanced automation, connectivity, and data analytics, welding processes are becoming more intelligent, efficient, and adaptable. Welding robots equipped with sensors and AI capabilities are revolutionizing production lines, enabling precise and consistent welds while optimizing resource utilization. Furthermore, integration with digital platforms facilitates real-time monitoring, quality control, and predictive maintenance, enhancing productivity and reducing downtime. In this digital age, welding technology serves as a cornerstone in achieving agile, smart manufacturing processes that are essential for meeting the demands of the rapidly evolving automotive landscape.

Improving Welding Technology in the Metalworking Industry

In the metalworking industry, enhancing welding technology is crucial for improving efficiency, quality, and safety. Strategies for improving welding processes may include adopting advanced welding techniques such as laser welding or friction stir welding, implementing robotic automation to increase precision and consistency, optimizing welding parameters through data analytics and simulation, and investing in employee training and development to ensure proficiency with new technologies. These strategies aim to streamline production, reduce defects, and enhance overall competitiveness in the metalworking sector.

The Impact of Material Selection on Welding Processes

Material selection is a critical factor that directly influences welding processes. Different materials possess varying physical and chemical properties, which significantly affect the welding process’s quality, efficiency, and feasibility. Factors such as melting point, thermal conductivity, expansion coefficient, hardness, strength, and surface condition of materials all play crucial roles in determining the appropriate welding technique, parameters, and outcomes. Therefore, careful consideration of material properties and requirements is essential in selecting the most suitable welding method and ensuring optimal welding results.

Quality Control and Assurance in Welding Processes

Ensuring quality control and assurance in welding processes is crucial for producing reliable and durable welds. This involves implementing systematic procedures and techniques to monitor, assess, and maintain the quality of welded joints throughout the fabrication process. Quality control measures may include rigorous inspection of materials, weld preparation, welding parameters, and post-weld treatments. Additionally, adherence to industry standards, certifications, and best practices is essential to guaranteeing weld integrity and performance. Overall, effective quality control and assurance practices are essential for achieving consistent and high-quality welds in various applications.

Gas Shielded Arc Welding and Gas Tungsten Arc Welding

Gas Shielded Arc Welding (GSAW) is a common welding method that utilizes inert gases (such as argon) or active gases (such as carbon dioxide) to protect the welding area from atmospheric contamination by oxygen and water vapor. During welding, an arc is generated between the electrode and the workpiece, causing melting and the formation of a weld bead. The use of gas shielding helps stabilize the arc and ensures the quality and cleanliness of the weld area.

Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas Welding (TIG), is a highly precise welding method. Using a non-consumable tungsten electrode and a pure argon shielding gas, GTAW produces a weld pool by generating an arc between the electrode and the workpiece. The argon gas not only protects the welding area from contamination but also stabilizes the arc, thereby improving weld quality and efficiency.

These two welding methods have their respective advantages and applications in practice, and the choice between them depends on specific requirements and material characteristics.

Future Directions and Challenges in Welding Technology

As manufacturing industries continue to advance and technology progresses, welding technology will also witness new developments and challenges in the future. The future of welding technology may involve the following aspects:

Automation and Robotics:

With the ongoing development of artificial intelligence and robotics, future welding processes will become more intelligent and automated. Automated welding systems will achieve highly flexible production, improving productivity and quality through intelligent control and collaborative robots.

Digitization and Virtualization:

Digital technology and virtual reality will play a crucial role in future welding processes. Through digital simulation and virtual reality technologies, precise simulation and optimization of welding processes can be achieved, enhancing welding quality and efficiency.

New Materials and Processes:

With the emergence of new materials and the development of new processes, future welding technology will face more challenges and opportunities. For example, welding processes for high-strength steel, composite materials, and lightweight materials will become key research areas in welding technology.

Environmental Protection and Energy Efficiency:

Environmental protection and energy efficiency will be important trends in the future development of welding technology. New welding technologies and materials will focus more on reducing energy consumption and emissions, achieving clean production, and sustainable development.

Talent Cultivation and Technology Popularization:

Future developments in welding technology will also require strengthening talent cultivation and technology popularization efforts. Cultivating high-quality welding talents and promoting advanced welding technologies will be crucial for the future development of welding technology.

Overall, the future direction of welding technology will be towards intelligentization, digitization, environmental protection, and talent cultivation. Faced with challenges, continuous innovation and improvement will be necessary to meet the increasingly complex and diverse manufacturing demands.

Conclusion:

Welding technology, pivotal to manufacturing, stands at the core of Shaoyi Company’s operations, ensuring the integrity and quality of our precision-engineered components. As we navigate the evolving landscape of the manufacturing industry, embracing advancements in welding processes becomes imperative. Shaoyi Company is committed to incorporating intelligent, digitized, and environmentally sustainable welding techniques into our operations, aligning with our dedication to innovation and excellence. Through ongoing talent development and technological innovation, Shaoyi Company is poised to lead in the realm of welding technology, driving sustainable growth and enhancing our competitive edge in the manufacturing sector.