Shao Yi’s Quality Mastery: Unveiling the “Seven Quality Control Tools” Perspective

Introduction:

In the intricate landscape of precision manufacturing, where every detail matters, quality control emerges as a linchpin in ensuring excellence. At Shao Yi, a leading force in automotive metal components, the commitment to quality is deeply ingrained, and a crucial aspect of our approach is the application of the “Seven Quality Control Tools” – a methodology often referred to as the “Seven Basic Tools of Quality.” In this extensive blog, we delve into the intricacies of these tools, exploring their significance, applications, and the unique perspective that Shao Yi brings to the mastery of quality control.

The Foundation of Quality Excellence:

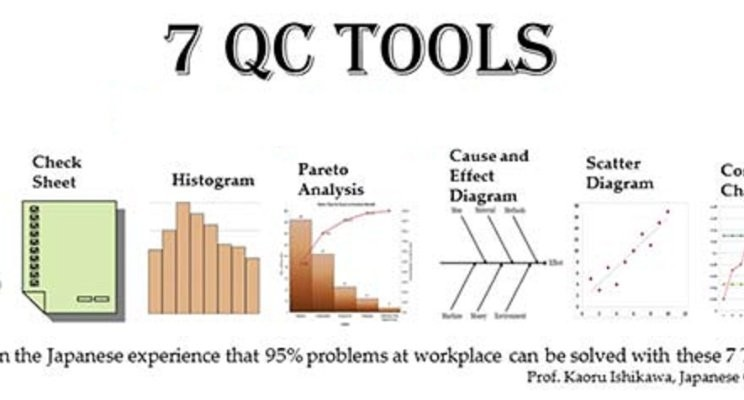

a. Defining the Seven Quality Control Tools:

The “Seven Quality Control Tools” refer to a set of fundamental techniques used in quality control and continuous improvement. Originating in Japan, these tools are timeless instruments that empower organizations to identify, analyze, and rectify issues in their processes.

b. Continuous Improvement Philosophy:

At Shao Yi, the adoption of the Seven Quality Control Tools is not merely a practice; it’s a philosophy. It aligns with our commitment to continuous improvement, where every process is seen as an opportunity to enhance efficiency, reduce defects, and ultimately deliver uncompromising quality to our customers.

The Seven Quality Control Tools: An Overview:

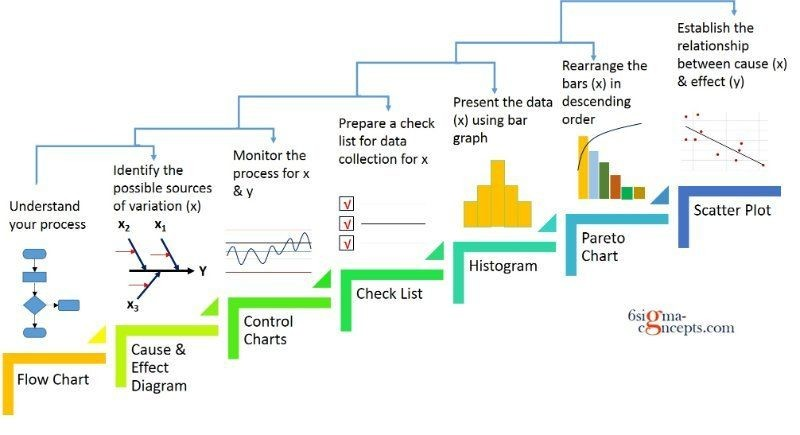

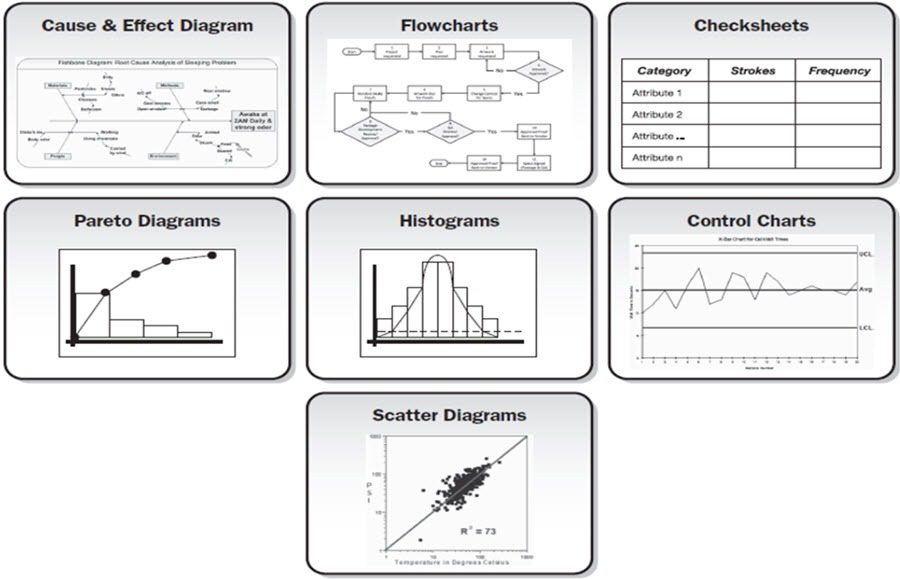

a. Check Sheets:

Check sheets, a fundamental tool, are employed at Shao Yi to systematically collect data. From recording defects in components to tracking machine downtime, check sheets provide a structured approach to gather information essential for analysis.

b. Histograms:

Histograms are graphical representations of data distribution. Shao Yi utilizes histograms to visualize the frequency and distribution of variations in our processes. This aids in identifying patterns and trends that may impact product quality.

c. Pareto Analysis:

Pareto Analysis, based on the Pareto Principle (80/20 rule), helps prioritize issues by focusing on the most significant factors contributing to defects. Shao Yi applies this tool to channel resources effectively and address critical issues that have the most substantial impact on quality.

d. Cause-and-Effect Diagrams (Fishbone or Ishikawa):

Cause-and-effect diagrams, often referred to as Fishbone diagrams, are instrumental in identifying the root causes of problems. Shao Yi employs these diagrams to facilitate cross-functional team discussions, leading to a comprehensive understanding of the factors influencing quality.

e. Defect Concentration Diagrams (Scatter Diagrams):

Defect Concentration Diagrams, or Scatter Diagrams, help visualize the relationship between two variables. Shao Yi utilizes this tool to identify correlations between process variables and defects, allowing for targeted interventions to improve specific aspects of our manufacturing processes.

f. Control Charts:

Control charts are indispensable in monitoring the stability and consistency of processes over time. At Shao Yi, these charts serve as a dynamic tool for real-time process control, allowing us to detect variations and make timely adjustments to maintain quality standards.

g. Stratification (Flowcharts):

Stratification, often executed through flowcharts, involves breaking down data into different categories for detailed analysis. Shao Yi applies stratification to gain insights into the nuances of our processes, identifying areas for improvement and implementing targeted solutions.

Shao Yi’s Approach to Quality Control Mastery:

a. Integrated Quality Culture:

Quality control at Shao Yi extends beyond tools; it is embedded in our organizational culture. Every team member is an integral part of the quality journey, fostering a collective commitment to excellence that transcends individual roles.

b. Cross-Functional Collaboration:

Shao Yi recognizes that quality control is a collaborative effort. Cross-functional teams, comprising experts from various disciplines, engage in the application of the Seven Quality Control Tools. This collaborative approach ensures a comprehensive understanding of processes and facilitates holistic problem-solving.

c. Data-Driven Decision-Making:

The Seven Quality Control Tools serve as a conduit for data-driven decision-making at Shao Yi. We emphasize the importance of accurate and timely data collection, analysis, and interpretation to inform decision-making processes that enhance the quality of our components.

d. Continuous Training and Skill Development:

Shao Yi invests in continuous training and skill development for our teams involved in quality control. Mastery of the Seven Quality Control Tools requires a deep understanding of their applications, and ongoing education ensures that our personnel remain at the forefront of quality excellence.

Real-World Applications in Automotive Manufacturing:

a. Defect Reduction:

Shao Yi’s application of the Seven Quality Control Tools has resulted in significant defect reduction. Through the systematic identification and analysis of root causes using tools like Fishbone diagrams and Pareto Analysis, we have been able to implement targeted solutions that minimize defects in our components.

b. Process Optimization:

Control charts and scatter diagrams are integral to Shao Yi’s approach to process optimization. By monitoring and analyzing process variations, we can fine-tune our manufacturing processes to operate within optimal parameters, ensuring consistency and efficiency.

c. Enhanced Customer Satisfaction:

The ultimate goal of quality control at Shao Yi is to enhance customer satisfaction. Through the meticulous application of the Seven Quality Control Tools, we have achieved not only a reduction in defects but also improvements in product reliability, meeting and exceeding customer expectations.

Challenges and Future Perspectives:

a. Challenges in Implementation:

Implementing the Seven Quality Control Tools comes with its set of challenges, including data accuracy, resistance to change, and ensuring sustained commitment. Shao Yi acknowledges these challenges and addresses them through a proactive approach that involves continuous improvement and adaptability.

b. Embracing Technological Advancements:

Shao Yi recognizes the evolving landscape of quality control with the advent of Industry 4.0 technologies. While the Seven Quality Control Tools remain foundational, we are also exploring how emerging technologies, such as artificial intelligence and advanced analytics, can complement and enhance our quality control methodologies.

c. Global Integration of Quality Standards:

As Shao Yi expands its global presence, aligning with international quality standards becomes paramount. The Seven Quality Control Tools provide a universal framework, and Shao Yi is committed to integrating these standards seamlessly across its operations worldwide.

Conclusion:

In the realm of precision manufacturing, the mastery of quality control is a journey, not a destination. Shao Yi’s commitment to quality excellence is epitomized by the rigorous application of the Seven Quality Control Tools. These tools, deeply embedded in our organizational culture, empower us to continuously evolve, improve, and deliver components that not only meet but exceed the stringent standards of the automotive industry. As we navigate the complex landscape of quality control, Shao Yi remains steadfast in its pursuit of mastery, leveraging the art and science of the Seven Quality Control Tools to shape the future of automotive manufacturing.