Shaoyi’s Salt Spray Test: Ensuring Quality Assurance Excellence

In today’s competitive manufacturing landscape, ensuring product quality is paramount. This is especially true for sectors like automotive, aerospace, electronics and construction . Here, stability and performance in diverse, often harsh, environments are non-negotiable. One essential tool for achieving this benchmark is the salt spray test, and in this domain, Shaoyi is a front-runner. This blog post will delve into the features and applications of the salt spray testand underscores Shaoyi’s unparalleled commitment to quality assurance.

Why Salt Spray Testing Matters

The salt spray test is pivotal for simulating the corrosive properties of metallic and non-metallic materials in a natural environment. It has the following key features:

Simulated Corrosive Environment: Salt spray testing exposes materials to intense corrosive effects over a short period of time by simulating conditions of salt spray, humidity and high temperatures.

Precision and Control: This test method is highly controllable, allowing the salt spray concentration, temperature and humidity to be adjusted to meet the needs of different applications.

Rapid Assessment: Salt spray tests are usually completed in a short period of time, so they can quickly assess the corrosion performance of a material or product, helping manufacturers to identify potential problems early.

Indispensable QA Tool: It’s instrumental in both quality assurance and quality control, ensuring that products work properly even in adverse conditions.

Shaoyi’s Innovations in Salt Spray Testing

Always at the forefront of salt spray testing, Shaoyi continually refines its techniques and equipment for precision-driven outcomes. Our pioneering efforts encompass:

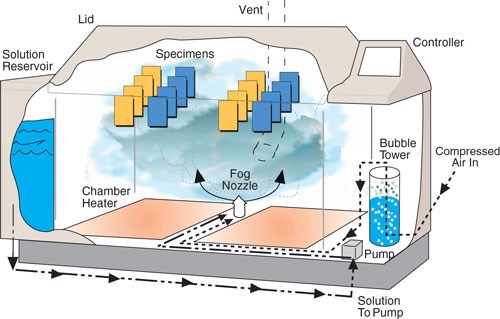

State-of-the-art Equipment: Investments in top-tier salt spray testing apparatus guarantee test accuracy and repeatability.

Customized Test Solutions: We provide our clients with customized salt spray test solutions, adapted to their product type and application requirements.

In-depth Data Insights: Comprehensive data analysis and reporting to help our customers understand the performance of their materials or products and provide recommendations for improvement.

Multi-disciplinary Applications: Our salt spray testing services cover a wide range of industries, including automotive, electronics, construction and aerospace, to name a few.

Salt Spray Testing Across Industries

Salt spray testing is used in a wide variety of applications, including but not limited to the following:

Automotive Manufacturing: In automotive manufacturing, parts and bodies are subjected to a variety of environmental conditions, including salt snow and road brine. Salt spray testing helps automakers ensure that their products remain durable in harsh weather.

Electronics: Electronics such as cell phones, computers and electronic circuit boards need to withstand humidity and corrosion to ensure long-term performance.

Building Materials: Salt spray testing can be used to evaluate the durability of building materials, especially at the beach or in salt-laden environments.

Aerospace: Aircraft components need to be able to operate in a variety of weather conditions, and salt spray testing helps ensure their performance and safety.

The Shaoyi Advantage: Benefits for Our Clients

Entrusting Shaoyi with salt spray testing translates to:

Unwavering Product Reliability: Salt spray testing ensures that products remain reliable under harsh conditions, reducing failure rates.

Top-Notch Quality Assurance: This testing method helps manufacturers ensure that their products meet quality standards, improving product quality and reliability.

Economical Solutions: By identifying potential problems early, customers can reduce the cost of repairs and replacement parts.

Boosted Customer Trust: Producing high quality, durable products increases customer satisfaction and customer loyalty.

Future Prospects

As industry frontrunners, Shaoyi’s commitment to excellence in salt spray testing remains unwavering. Adapting to evolving market needs, we persist in enhancing our testing protocols and tools. As manufacturing pivots around quality and durability, our promise is to equip our clients with superior testing tools, steering them towards success. We cherish your support and look forward to co-navigating future challenges.