The Three Major Processes and Future Development Trends of Automotive Component Manufacturing

Itroduction:

Automotive component manufacturing is a crucial part of the automotive industry. In automotive component manufacturing, die-casting, machining,stamping are the three most common processes. I will take you to understand these three processes of our company. And discuss with you the future development trends of the automotive manufacturing industry.

Die Casting

Process Introduction

Die casting is a common metal processing technique commonly used to produce aluminum alloy components with complex structures. This process involves injecting molten metal into a mold, which is then cooled under high pressure. Die casting technology has the characteristics of high production efficiency and low cost, and is suitable for large-scale production.

Application field

Die casting technology is widely used in automobile manufacturing, producing engine cylinder blocks, transmission system parts, braking system parts, etc. For example, the engine cylinder block and crankcase are usually manufactured using die casting technology. To ensure the accuracy and strength of the parts. Nowadays, the demand for lightweight in automobile manufacturing is increasing.And die-casting manufacturing technology precisely conforms to the characteristics of lightweight. While ensuring lightweight, it also maintains metallic stiffness, providing safety for the vehicle.

Machining

Process Introduction

Machining is the process of processing raw materials into the desired shape through cutting or grinding methods. Machining includes operations such as turning, milling, and drilling, which can achieve high-precision and complex structural component manufacturing.

Application Field

Machining technology is widely used in various aspects of automobile manufacturing, producing engine parts, chassis parts, suspension system parts, etc. For example, components such as engine crankshafts and camshafts typically require precision machining.

Stamping

Process Introduction

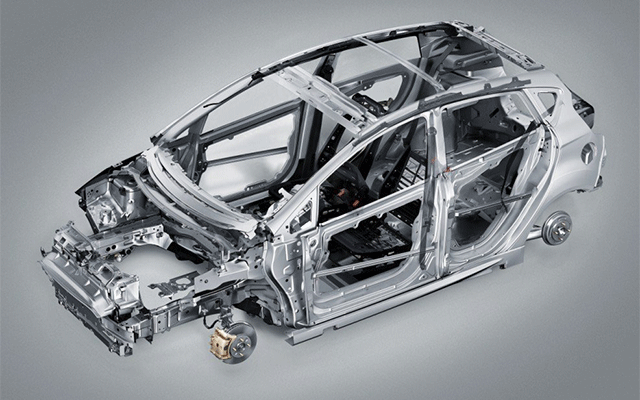

Stamping is a process in which metal sheets are subjected to pressure in a mold to form the desired shape. Stamping technology is suitable for producing large quantities of metal parts with simple shapes. We as the characteristics of high production efficiency and low cost.

Application Field

Stamping technology is widely used in automobile manufacturing, producing body structural components, doors, engine covers, etc.

sheet metal parts of car bodies are usually manufactured using stamping to ensure the shape.

Automobile Manufacturing Industry Tendency

Intelligent manufacturing

Intelligent manufacturing

In the future, the automotive manufacturing industry will pay more attention to the development of intelligent manufacturing.

By introducing artificial intelligence, big data, and Internet of Things technology. Automation and intelligent management of production lines can be achieved, improving production efficiency and product quality.

For example, German automaker Audi has introduced an intelligent manufacturing system that achieves intelligent management. Of production lines through data analysis and predictive maintenance, greatly improving production efficiency.

And we have also introduced digital workshops, which provide support for Shaoyi’s data-driven decision-making.

Light weighting

In the future, the automotive manufacturing industry will pay more attention to the application of lightweight technology.

Adopting advanced materials and designs, such as carbon fiber composite materials and aluminum alloys, to achieve lightweight automotive components and improve fuel efficiency and performance.

For example, Tesla uses a large amount of aluminum alloy materials and carbon fiber composite materials to achieve lightweight design of its electric vehicles, greatly extending the range.

And one of the main raw materials for our products now is aluminum, which has excellent rigidity and lightweight characteristics, and is also one of the many materials used in cars today.

Sustainability development

The future automobile manufacturing industry will pay more attention to the concept of sustainable development.

Adopting environmentally friendly materials and energy-saving processes to reduce carbon emissions and energy consumption in the automotive production process, achieving a green transformation of the automotive manufacturing industry.

For example, Japanese automaker Toyota has introduced the concept of an ecological factory, which provides clean energy supply to factories through renewable energy sources such as solar and wind energy, reducing environmental pollution.

Through continuous innovation and technological progress, the future automotive manufacturing industry will usher in more prosperous development, bringing more opportunities and challenges to the global automotive industry.

Through continuous innovation and technological progress, the future automotive manufacturing industry will usher in more prosperous development, bringing more opportunities and challenges to the global automotive industry.